7 Common Accessories for Filter Presses

A filter press relies on a series of key accessories for operation. These accessories not only ensure stable operation but also impact filtration efficiency and service life. Below is a brief description of common filter press accessories and their functions.

Filter Plates

Function

Two filter plates form the filter chamber, withstand the pressure during filtration, and work with the filter cloth to separate solids and liquids.

Classification

- Chamber filter plates: These plates have internal grooves and form a filter chamber when paired together.

- Plate and frame filter plates: These plates are composed of a solid plate and a frame, alternating to form a filter chamber.

- Membrane filter plates: These plates have an elastic diaphragm on the outside that allows for the injection of gas/liquid for secondary compression, increasing the cake’s density.

Materials

Polypropylene: Corrosion-resistant, lightweight, and the most widely used.

Cast Iron/Stainless Steel: High-temperature and high-pressure resistant, used in specialized industries such as metallurgy and chemicals.

Selection recommendations

- Choose polypropylene for corrosion resistance.

- Choose a membrane filter plate for high-pressure dehydration.

- Choose a stainless steel filter plate for high-temperature filtration.

Filter Cloth

Function

Serves as a carrier for the filter medium, filtering liquids and retaining solid particles.

Common Materials

Polyester (PET), Polypropylene (PP), Nylon (PA)

Weaving method

Plain, twill, satin, etc., determine the balance between filtration accuracy and water permeability.

Common causes of filter cloth blockage or damage

- Parts of the filter cloth include: Excessively fine particles or a lack of pretreatment.

- Untimely cleaning, resulting in a dirty filter cloth.

- Improper installation of the filter cloth.

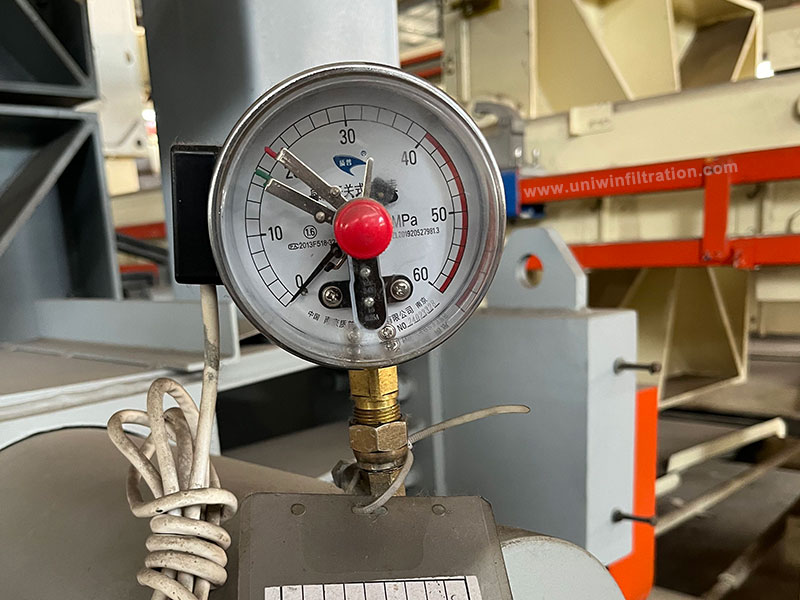

Pressure Gauge

Function

Real-time monitoring of the filter press’s operating pressure (such as feed pressure or hydraulic system pressure) is a key component for determining equipment operating status and ensuring safety.

Types

Ordinary pressure gauges: Typically used to measure the filter press’s feed pressure, they are primarily installed on the filter press’s feed line.

Electric contact pressure gauges: A type of filter press pressure gauge. Compared to ordinary pressure gauges, they feature a signal transmission function. When the set pressure is reached, they send a signal to the control cabinet to stop or start the filter press. They are primarily installed on hydraulic cylinders to measure the filter press’s oil cylinder pressure.

Filtrate Collection Groove

Function

Collects clear liquid from beneath the filter plates, preventing spillage and contamination. It can be piped for centralized discharge or reuse. The design and function of the filtrate collection groove are crucial to ensuring efficient collection and transport of filtrate to storage or other processing facilities.

Material

Materials include stainless steel, carbon steel with a corrosion-resistant coating, or polyethylene plastic.

Conveyor

Function

Receives filter cake discharged from the filter press and continuously conveys it to a designated area (such as a storage yard, silo, or transport vehicle). This increases automation and reduces manual labor.

Structure Type

Belt Conveyor: Smooth operation, suitable for both wet and dry materials.

Screw Conveyor: A motor-driven screw conveyor propels materials for conveying. Screw conveyors can convey materials horizontally, inclined, or vertically.

Control Method

It can be linked to an automatic plate puller system for automatic conveying after cake discharge.

Automatic Washing System

Function

The cleaning device moves up and down the filter cloth surface, performing high-pressure cleaning to remove residual filter cake, fine particles, and oil, maintaining filtration efficiency.

Operating Principle

A high-pressure water nozzle is installed to clean the filter cloth synchronously or periodically with the movement of the filter plates.

Advantages

- Extends filter cloth life;

- Reduces manual cleaning frequency;

- Improves filtration accuracy and permeability.

Drip Tray

Function

Installed beneath the filter press, the flap closes during filtration, allowing the filtrate to flow along the flap into the collection tank to prevent wetting the filter cake. After filtration is complete, the flap opens, allowing the filter cake to fall onto the conveyor belt below for transport to another location.

Structural Components

The flap mechanism is typically installed beneath the filter plate and can be controlled pneumatically, hydraulically, or electrically.

Conclusion

Filter presses have a wide variety of accessories, and the synergy of these components determines the overall performance and efficiency of the machine. During operation, it is recommended to regularly check the condition of key accessories and promptly replace worn parts to maintain stable and efficient operation.