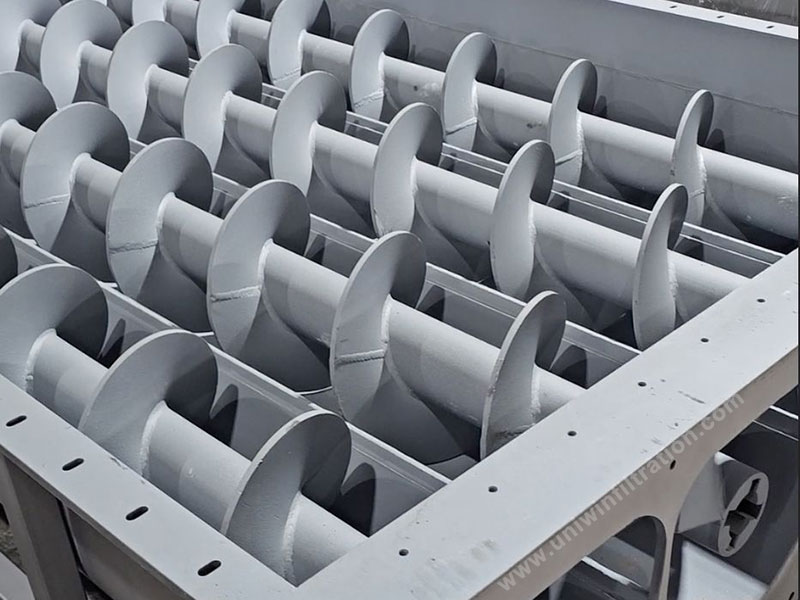

Shafted Screw Conveyor

A shafted screw conveyor is a common mechanical conveying equipment widely used in industries such as sludge conveying, chemicals, food, and building materials. It is especially suitable for conveying high-viscosity, easily entangled materials, such as municipal sludge, pulp, and domestic waste.

What is a Shafted Screw Conveyor?

A shafted screw conveyor (also known as a screw conveyor with a shaft) is a continuous conveying device that uses rotating helical blades to propel materials along a casing. Compared to shaftless screw conveyors, it features a central shaft at the center of the helical blades, enhancing structural stability and making it suitable for conveying materials that are not prone to tangling.

Main Structural Components

- Helical blades: Welded to the central shaft, used to propel materials forward. Blade shapes are mostly solid, but ribbon-like and paddle-shaped blades also exist.

- Central shaft: Runs through the entire length of the conveyor, serving as the core support for the helical motion.

- Shell: Usually U-shaped or cylindrical, it protects and supports the materials.

- Inlet/Outlet: Material enters through the inlet and is pushed towards the outlet by the spiral blades for discharge.

- Drive unit: Composed of a motor and reducer, used to drive the spiral shaft to rotate.

- Hanger bearings and end bearings: Support the long shaft structure and reduce axial and radial misalignment during operation.

Shafted Screw Conveyor VS Shaftless Screw Conveyor

Structural differences

The core of a shafted screw conveyor lies in its central main shaft, with helical blades welded to this shaft. A motor drives the blades to rotate, propelling the material forward.

A shaftless screw conveyor, on the other hand, completely eliminates the central shaft, relying on the torque of the highly rigid shaftless screw itself to transmit power and propel the material.

Applicable material types

Shafted screw conveyors are suitable for dry, free-flowing, granular, or powdery materials. These materials have lower requirements for the conveying environment, are less prone to tangling, and will not clog the central shaft.

Shaftless screw conveyors are more suitable for materials with high moisture content, high viscosity, or fibrous and easily tangled properties, such as municipal sludge, domestic waste, and paper mill pulp.

Conveying performance

Shaftless screw conveyors, due to the absence of a central shaft, are more efficient and less prone to clogging when conveying materials with high moisture content, large volume, and numerous impurities.

However, shafted screw conveyors offer greater stability in long-distance conveying and structural strength, making them particularly suitable for horizontal or slightly inclined conveying.

Wear resistance and service life

The screw of a shaftless screw conveyor is usually thicker, and there is a liner between it and the trough, resulting in more even wear. In contrast, the main wear areas of a shafted screw conveyor are concentrated on the central shaft, hanger bearings, and bushings; these components require regular replacement or maintenance.

Advantages of Shafted Screw Conveyors

More stable structure

Shafted screw conveyors are equipped with a central shaft and hanger bearings, resulting in high overall rigidity and structural stability. This makes them particularly suitable for applications requiring long conveying distances. The deflection of the screw shaft can usually be effectively controlled by installing intermediate hanger bearings, ensuring long-term stable operation.

Suitable for dry, free-flowing materials

When the material is dry powder, granules, or a type that is free-flowing and not easily tangled, the shafted screw conveyor has higher conveying efficiency, smoother operation, and lower running resistance.

Lower energy consumption

For the same conveying conditions, shafted structures have less friction surface, and the central shaft shares part of the load, resulting in lower overall conveying resistance compared to shaftless structures. This leads to lower energy consumption and more stable efficiency during operation. This is especially true for horizontal conveying or small-angle inclination.