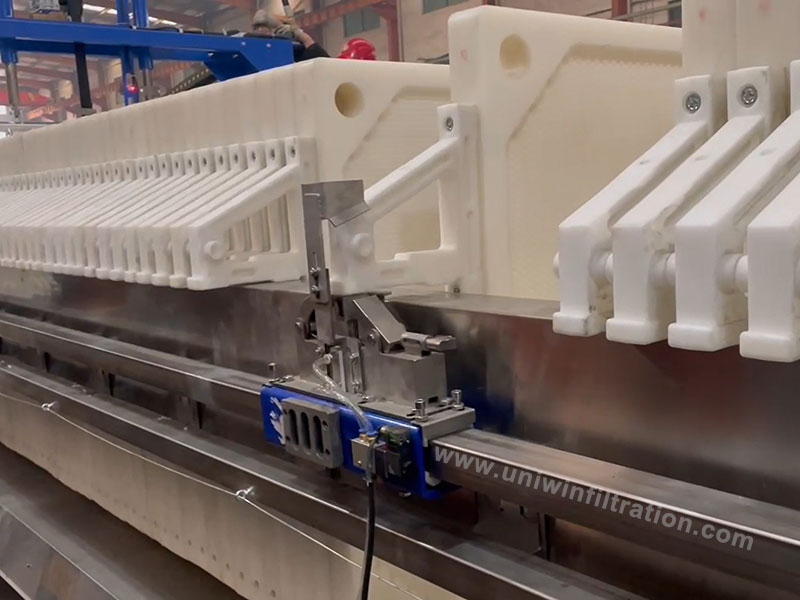

Vibrating Filter Press

A vibrating filter press (i.e., a filter press with a vibrating device) is a device that adds a filter cake removal function to the conventional filtration process. It is mainly used in situations where the filter cake has strong adhesion and is not easy to fall off naturally.

Through the mechanical action of the vibrating device, the peeling effect of the filter cake from the filter cloth is enhanced, the unloading efficiency is improved, and manual intervention is reduced.

Working Principle of a Vibratory Filter Press

A vibratory filter press, in addition to completing the basic processes of filtration, pressing, and unloading, adds a vibrating step. The specific steps are as follows:

Solid-Liquid Separation Stage: Under pressure, the filtrate flows out through the filter cloth, and the solids form a filter cake on the filter cloth.

Pressing Stage (Optional): Some models are equipped with gas or liquid pressing functions to further reduce the moisture content of the filter cake.

Opening and Discharging: After the filter plates open, the filter cake begins to fall off naturally.

Vibration Assistance: If the filter cake adheres to the filter cloth, the vibration system is activated to vibrate the filter plates or filter cloth, causing the remaining filter cake to fall off quickly.

Advantages of Vibratory Filter Presses

Increased Filter Cake Removal Rate: Significantly reduces residue on the filter cloth, especially suitable for highly viscous and easily clogged materials.

Reduced Manual Cleaning: Vibration replaces some manual cake-shaking work, reducing labor intensity.

Improved Unloading Efficiency: Rapid filter cake removal shortens the unloading cycle and improves overall equipment efficiency.

Extend the life of the filter cloth: Avoid forcibly pulling the filter cake, which may damage the filter cloth.

Applicable Industries

Fine Chemicals (e.g., pigments, dyes, auxiliaries, etc.)

Pharmaceuticals and Bio-fermentation

Non-ferrous Metal Smelting

Wastewater Treatment and Municipal Engineering

Food and Beverage Processing (e.g., soy sauce, starch, vegetable protein, etc.)

Selection Recommendations

When selecting a vibratory filter press, pay close attention to the following parameters:

Material viscosity and filter cake structure: Check for strong adhesion, cake formation, or other issues that make the filter cake difficult to remove.

Filter cloth type: Choose a filter cloth material compatible with vibratory operation (e.g., polypropylene);

Processing capacity requirements: Determine the required filtration area and level of automation.

Equipment material: Select corrosion-resistant materials for corrosive media (e.g., stainless steel, polypropylene frame);

Control system: Consider whether it is equipped with intelligent vibratory control, alarms, and timing functions.