Common Problems and Solutions for Filter Presses

Filter presses, as efficient solid-liquid separation equipment, are widely used in chemical, metallurgical, pharmaceutical, food, and environmental protection industries. During long-term operation, some common problems inevitably arise. The following are common problems encountered during the use of filter presses and their corresponding solutions.

Frequently Asked Questions and Solutions

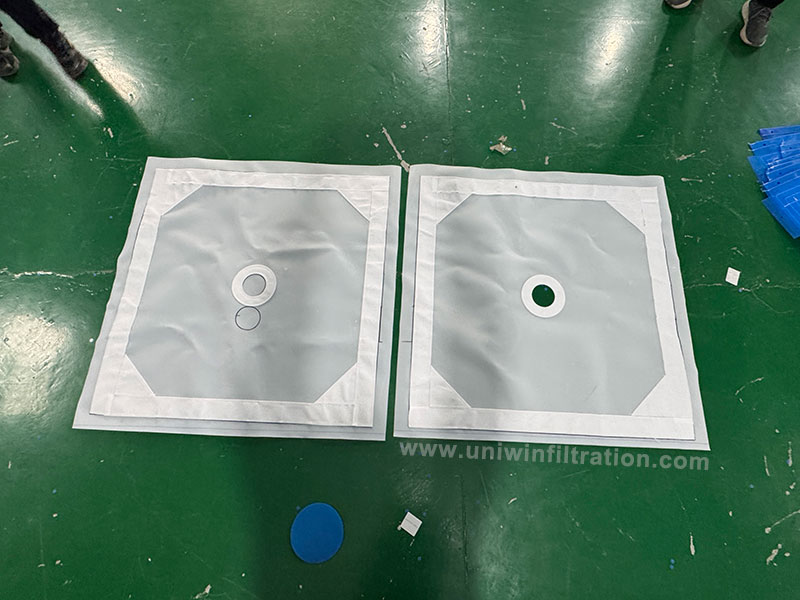

Filter Plate Leakage

Problem description: Water leaks between the filter plates during the filtration process, resulting in significant filtrate leakage and affecting the filtration efficiency.

Possible causes:

- The filter cloth is wrinkled or damaged.

- There are impurities or damage on the sealing surface of the filter plate.

- The filter plates are not aligned or properly installed.

Solutions:

- Check and re-lay the filter cloth, ensuring it is flat and wrinkle-free.

- Clean the sealing surface of the filter plate to remove sludge and debris.

- Replace damaged filter cloth or filter plates.

High Moisture Content in the Filter Cake

Problem description: The filter cake is too wet, resulting in unsatisfactory dewatering.

Possible causes:

- Low feed concentration, insufficient solid content.

- Insufficient filtration pressure or short filtration time.

- Filter cloth clogging, resulting in slow filtration speed.

- Improper filter cloth selection, poor water permeability.

Solutions:

- Adjust the feed concentration to increase the solid content of the slurry.

- Increase the filtration pressure or extend the filtration time; check the pressing system to ensure uniform pressure on the filter plates.

- Clean or replace the clogged filter cloth.

- Select a filter cloth with an appropriate material and pore size.

Filter Cloth Clogging

Problem symptoms: Slow filtration speed, difficulty in filter cake formation.

Possible causes:

- The filter cloth is clogged due to prolonged use without cleaning.

- An unsuitable type of filter cloth is being used.

- The feed material particles are too fine, leading to clogging.

Solutions:

- Clean the filter cloth regularly; if necessary, use high-pressure water or chemical cleaning.

- Replace the filter cloth with a type suitable for the current material properties.

- Pre-treat the material (e.g., add flocculants) to increase particle size.

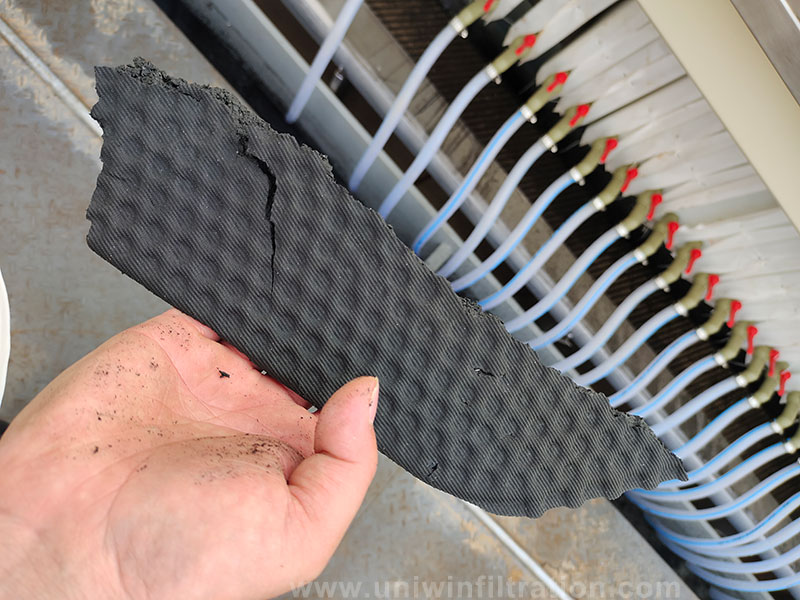

Filter Plate Cracking or Deformation

Problem description: The filter plate surface shows cracks, swelling, or depressions, affecting sealing and filtration efficiency.

Possible causes:

- Excessive pressure or sudden pressure changes.

- Aging or quality issues of the filter plate material.

- Uneven stress on the filter plate or incorrect installation.

Solutions:

- Control the operating pressure of the filter press within the rated range.

- Regularly inspect the filter plates and replace them promptly if cracks are found.

- Follow standardized operating procedures to avoid abnormal impacts.

Hydraulic System Malfunction

Problem symptoms: failure to clamp or release filter plates, insufficient or unstable pressure.

Possible causes:

- Hydraulic oil leakage or deterioration.

- Worn cylinder seals.

- Hydraulic pump malfunction.

Solutions:

- Check the hydraulic oil level and replace the hydraulic oil regularly.

- Inspect the seals and replace worn parts promptly.

- Repair or replace hydraulic pump components.

The Filter Press Cannot Automatically Discharge the Filter Cake

Problem description: The filter cake adheres to the filter cloth or filter plate, making it difficult to detach automatically.

Possible causes:

- The filter cloth has strong adhesion, making it difficult to peel off the filter cake.

- Problems with the material properties, such as high viscosity or the filter cake not forming properly.

- Poor surface condition of the filter cloth.

Solutions:

- Select a type of filter cloth that facilitates easy cake release.

- Adjust the material ratio or perform pretreatment (e.g., adding PAM or PAC).

- Add an automatic vibration device or an auxiliary cake discharge system.

Feed Pump Frequently Starts and Stops or Becomes Clogged

Problem symptoms: Unstable feeding, interruption of the filtration process.

Possible causes:

- Incorrect pump selection, unable to meet system requirements.

- Pump pipeline blockage or air ingress.

- Slurry contains large particles or foreign matter.

Solutions:

- Replace with a feed pump of appropriate specifications.

- Clean the pipeline to prevent cavitation.

- Install a filter screen or pre-treatment system before feeding.

Routine Maintenance Suggestions

- Regularly inspect the filter cloth, filter plates, and seals.

- Keep the equipment clean, especially the sealing surfaces and hydraulic system.

- Thoroughly clean the equipment after each operation to prevent residue from drying and hardening.

- Maintain detailed operating records to facilitate troubleshooting.

Conclusion

Filter presses inevitably experience various malfunctions during long-term operation, but through standardized operation, regular maintenance, and timely troubleshooting, the equipment’s lifespan can be effectively extended and operational efficiency improved. Companies should strengthen operator training to ensure the safe and stable operation of the equipment.