What is a Filter Press?

A filter press is an industrial equipment widely used in solid-liquid separation processes, especially in the fields of chemical, pharmaceutical, food, environmental protection, mining, and sewage treatment. It squeezes out the liquid in the material by pressurizing it to achieve efficient separation of solid and liquid. It has the characteristics of compact structure, high filtration efficiency, and simple operation.

With the tightening of environmental protection policies and the advancement of industrial upgrading, the market demand and technical level of filter presses, as key environmental protection equipment, are constantly improving.

Working Principle of Filter Press

The core principle of the filter press is to separate solid and liquid under pressure through a filter medium (filter cloth). Its working process is as follows:

- Feeding stage

The slurry is delivered to the filter press chamber by the feed pump. - Filtration stage

The liquid is forced through the filter cloth under pressure, emerging as filtrate and being discharged, while solid particles are retained on the cloth’s surface, gradually forming a filter cake. - Pressing stage (diaphragm filter press)

The diaphragm filter press has the function of membrane plate pressing, which further squeezes out the moisture in the filter cake by pressurizing and improves the cake thickness. - Discharging stage

The filter plate is opened, and the filter cake falls off or is unloaded by the auxiliary system, completing a working cycle.

Main Accessories of Filter Press

Filter plate

The filter plate is the core structural component of the filter press and is used to construct the filter chamber. Its function is to clamp the filter cloth and withstand the filtering pressure to ensure that the slurry completes the solid-liquid separation in the cavity. Common materials include reinforced polypropylene, cast iron, or stainless steel.

Filter cloth

The filter cloth is the filter medium for filtering and separation. It is installed on the surface of the filter plate to intercept solid particles and allow liquid to pass through. The pore size and material of the filter cloth directly determine the filtering accuracy, efficiency, and filter cake shedding. The material usually includes polyester, polypropylene or polyester, etc.

Hydraulic system

The hydraulic system controls the opening and closing of the filter plates and provides the necessary pressure for the filtration process. It is the power source for the filter press to achieve the tightening and loosening action. The system includes hydraulic cylinders, oil pumps, oil tanks, and control valves.

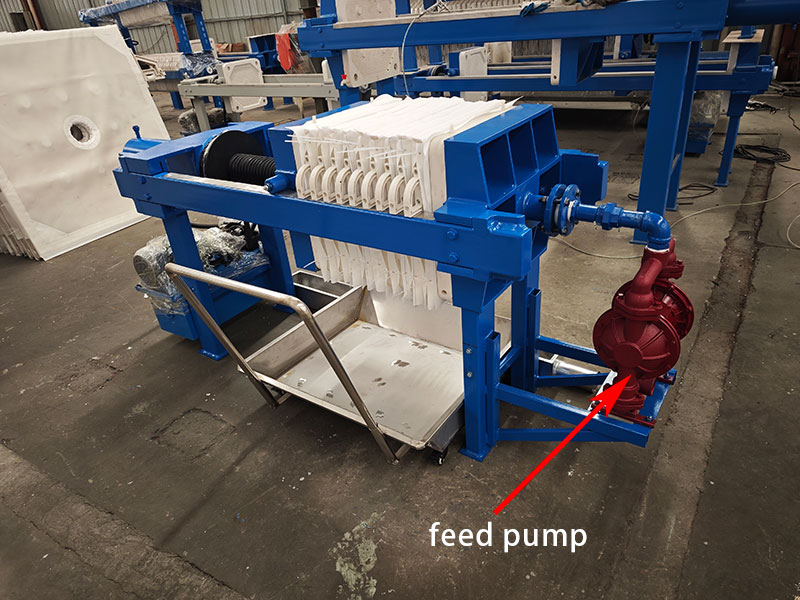

Feed pump

The feed pump transports the slurry to the filter chamber. It must have strong wear and corrosion resistance and can provide a certain flow rate and pressure. Common pump types include screw pumps, centrifugal pumps, diaphragm pumps, etc.

Main Advantages of the Filter Press

- High filtration efficiency

Can achieve the dual goals of a high solid recovery rate and clarified liquid. - High filter cake density

Especially the membrane filter press, which has strong dewatering capacity and is convenient for subsequent treatment or recycling. - High degree of operational automation

Modern filter presses feature PLC control systems that minimize manual intervention while enhancing operational safety and efficiency. - Wide range of applications

Can handle various types of suspensions, including highly corrosive, high temperature, or high concentration materials. - Low maintenance cost

Simple structure, key components are wear-resistant and corrosion-resistant, and operation is stable and reliable.

Conclusion

As an indispensable solid-liquid separation equipment in modern industry, the filter press plays an important role in various industries with its high efficiency, stability, and customizability. Selecting the appropriate filter press type and supporting system can significantly enhance production efficiency while reducing operating costs and minimizing environmental impact. If you have specific needs in model selection, parts replacement, or system optimization, please contact us for more technical support.