Filter Cloth of the Filter Press

In modern industrial filtration systems, filter cloth serves as the core medium between the filter plate and the filter cake. Its performance plays a crucial role in the overall efficiency of the filter press and the clarity of the filtrate. Whether in mining, chemical, pharmaceutical, environmental protection, or food processing industries, selecting the right filter cloth is crucial for achieving efficient solid-liquid separation.

What is Filter Cloth?

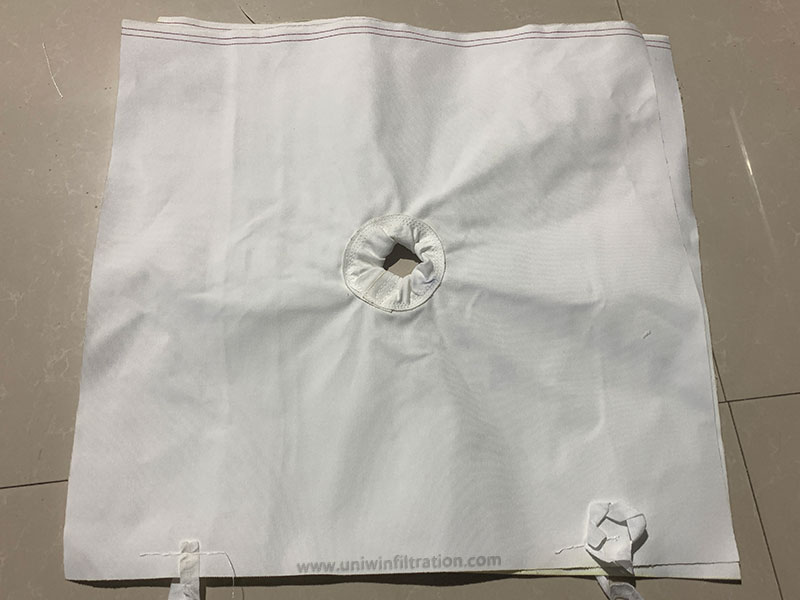

Filter cloth is a filtration medium made by weaving natural or synthetic fibers. It is an industrial fabric used for solid-liquid separation and is often installed on filter presses or vacuum filtration equipment. Its basic function is to effectively intercept solid particles while maintaining permeability to achieve liquid filtration and recovery.

Main Types of Filter Cloth

Classification by material

- Polyester: Abrasion-resistant, acid- and alkali-resistant, suitable for most industrial applications.

- Polypropylene: Chemically stable, suitable for handling highly corrosive liquids.

- Nylon: Highly strong and impact-resistant, but with slightly lower chemical resistance.

- Vinylene: Highly absorbent, suitable for specific filtration processes.

Classification by weave

- Plain weave filter cloth: Offers a stable structure and moderate filtration accuracy, widely used in conventional filter press equipment.

- Twill weave filter cloth: Provides improved drainage performance, suitable for dewatering filter cakes with high moisture content.

- Monofilament/multifilament filter cloth: Monofilaments have high porosity and are easy to clean; multifilament filter cloths have a compact structure and offer higher filtration accuracy.

Classification by filtration refinement

Filter cloth pore sizes typically range from 1 to 200 microns and can be selected based on the particle size and separation requirements. The level of filtration directly impacts the clarity of the filtrate and the solid content of the filter cake.

How to Choose the Right Filter Cloth?

Choosing the right filter cloth is essential, as it significantly influences the filtration process. A properly selected filter cloth directly impacts both filtration efficiency and processing speed. When selecting a filter cloth, consider the basic properties of the slurry and the filtration requirements, along with the cloth’s permeability (water or air permeability), filtration level (maximum and minimum pore size and porosity), service life (tensile strength and elongation), structure and weave, chemical properties, and cost.

During the filter selection process, it is recommended to comprehensively evaluate the following parameters:

- Filter media particle size and chemical properties

- Target filtration efficiency and filtrate clarity

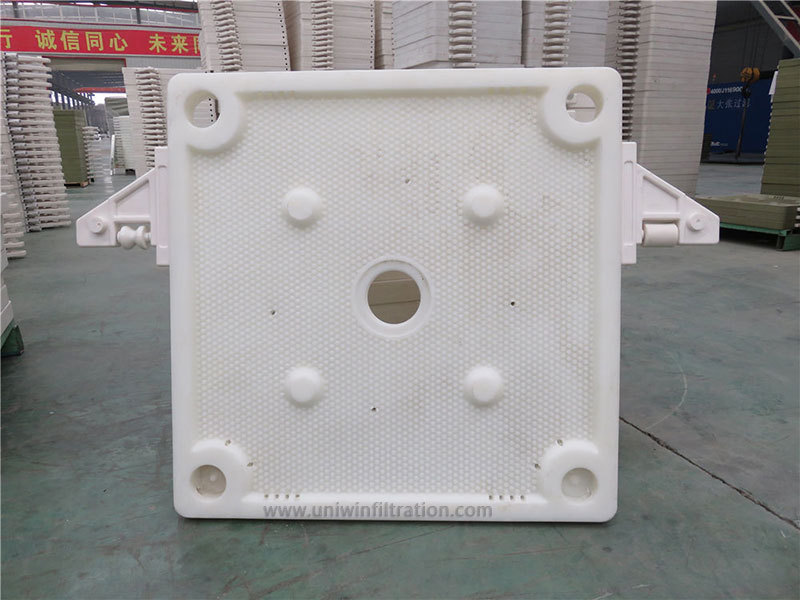

- Filter press type (plate and frame, chamber, membrane, belt, etc.)

- Filter cloth replacement and cleaning frequency

- Operating temperature and pH environment

Application Examples of Filter Cloths in Different Industries

- Mineral Processing: When handling high-concentration slurries, wear-resistant polyester filter cloth is used to ensure efficient dewatering.

- Food Industry: Whey filtration and juice clarification require food-grade filter cloth to ensure hygiene and safety.

- Chemical Industry: Filtering concentrated acid and alkali solutions requires corrosion-resistant polypropylene filter cloth.

- Sludge Dewatering: Environmental protection uses large-pore twill filter cloth to improve filter cake density and reduce subsequent processing costs.

Filter Cloth Installation Video

Filter Cloth Maintenance Recommendations

- Use a high-pressure water jet for regular backwashing.

- Avoid contact with hard objects to prevent damaging the filter cloth.

- Use a neutral detergent to prevent fabric degradation.

- Determine whether replacement is necessary based on declining filter performance.