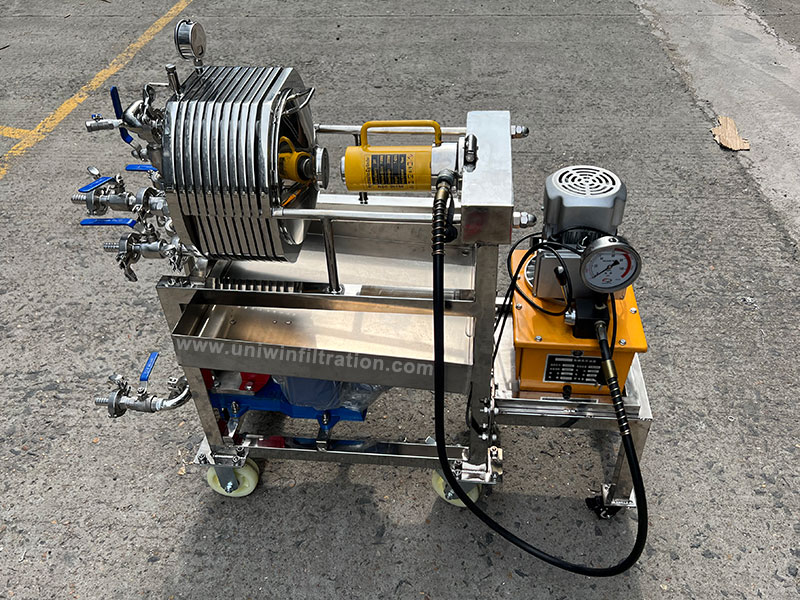

Stainless Steel Plate and Frame Filter

Stainless steel plate and frame filter is a common type of liquid-solid separation equipment, widely used in the food, pharmaceutical, chemical, and environmental protection industries. Made of high-quality stainless steel, they feature a compact structure, strong corrosion resistance, and easy cleaning. The following is a detailed introduction to stainless steel plate and frame filters to help you fully understand their structure, operating principles, application scenarios, and advantages.

Stainless Steel Plate and Frame Filter Structure

Filter plates and filter frames

Alternating filter plates and filter frames form the filter chamber, typically made of 304 or 316L stainless steel, suitable for a variety of corrosive liquids.

Filter media

Common media include filter cloth, filter paper, and microporous filter membranes. The appropriate material should be selected based on the filtration accuracy.

Compressing device

Usually uses manual, mechanical, or hydraulic methods to ensure a tight seal between the filter plates and frame.

The feed pump and piping system

Used to transport the liquid to be filtered into the filter.

The frame and base

Support the entire filtration system and ensure stable operation.

Working Principle of the Stainless Steel Plate and Frame Filter

- The feed liquid enters the filter chamber under the action of a feed pump.

- The liquid passes through the filter media, trapping impurities and achieving solid-liquid separation.

- The clear liquid is discharged from the outlet, while the filter residue remains on the filter cloth.

- If the filter cloth becomes clogged or the pressure differential is excessive, the equipment must be stopped and disassembled for cleaning or replacement of the filter media.

Advantages of Stainless Steel Plate and Frame Filter

High corrosion resistance and strong adaptability

Stainless steel plate and frame filters are typically manufactured from 304 or 316L stainless steel, effectively resisting corrosion from most acidic and alkaline media. They are particularly suitable for filtering high-purity liquids and chemical fluids containing corrosive components.

High filtration precision, supporting a variety of filter media

The device supports a variety of filter media: filter cloth is suitable for coarse and clarifying filtration, filter paper is suitable for medium-precision filtration, and microporous membrane filter can achieve a precision of 0.1μm, meeting sterile-grade requirements.

Flexible structure, easy to expand

The plate-and-frame structure allows for flexible addition and subtraction of filter plates, adjusting processing capacity as needed. It’s suitable for production scales ranging from small laboratory batches to large industrial batches.

Excellent sealing and stable operation

A mechanical or hydraulic clamping system creates a reliable seal between the plate and frame, preventing material leakage and ensuring stable filtration pressure.

Easy to clean, meeting hygiene standards

The smooth stainless steel surface is easy to clean and can be configured with a CIP system for in-place cleaning. The material complies with the Food and Drug GMP standards.

Plate and Frame Filter Applications

- Food and beverage: Fine filtration of liquids such as alcohol, juice, syrup, soy sauce, and vinegar;

- Pharmaceutical industry: Clarification and filtration of traditional Chinese medicine extracts and biological preparations;

- Fine chemicals: flavors and fragrances, catalyst recovery, resin solution purification, decarbonization.

- Environmental engineering: Solid-liquid separation pretreatment in wastewater treatment.

Decarbonization On-Site Video

Maintenance and Care Tips

- Regularly check the integrity and cleanliness of the filter cloth/paper.

- After shutting down, drain any residual liquid promptly to prevent the accumulation of scale.

- Pay attention to the aging of pipes and seals to prevent leaks.

- Keep the equipment dry and well-ventilated during storage to prevent corrosion.