High-Temperature Filter Plates

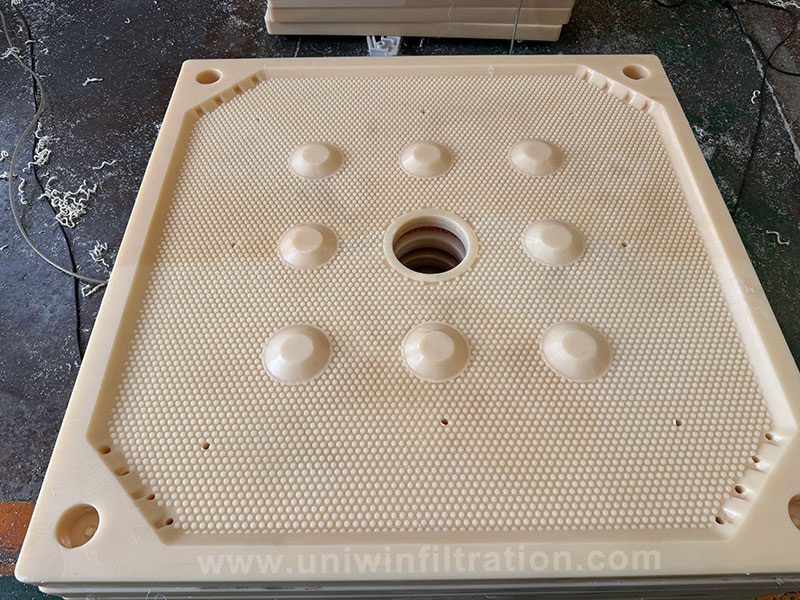

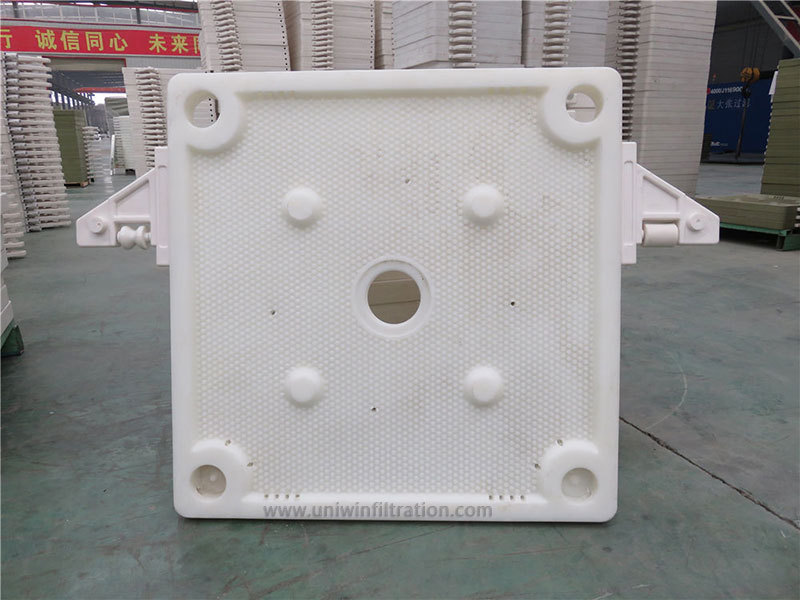

High-temperature filter plates are typically made from high-temperature resistant materials (with special formulations or modified additives) and are specifically designed for use in filter presses handling high-temperature slurries or filtrates. They are an essential and critical component in high-temperature filtration applications.

What are High-Temperature Filter Plates?

High-temperature filter plates are specially designed for solid-liquid separation in high-temperature process environments (≥80°C). Compared to standard filter plates (which typically operate at temperatures between 60°C and 70°C), high-temperature filter plates offer significantly improved temperature resistance, allowing stable operation at temperatures around 100°C and, depending on the material, even reaching 120°C or higher.

It is widely used in chemical, pharmaceutical, mining, ceramic, dye, and other industries, especially in scenarios such as hot filtration, concentration and dehydration, high-temperature degreasing, cooking and filtration, showing higher reliability and durability.

Advantages of High-Temperature Filter Plates

Higher temperature resistance

Ordinary filter plates are prone to softening, deformation, and edge leakage at temperatures above 60-70°C. High-temperature filter plates, however, significantly enhance their thermal stability by adding glass fiber, mineral fillers, or using polymer composite materials. They offer a typical temperature resistance of up to 100°C, and some materials can withstand even higher temperatures.

More stable structure under high pressure and temperature

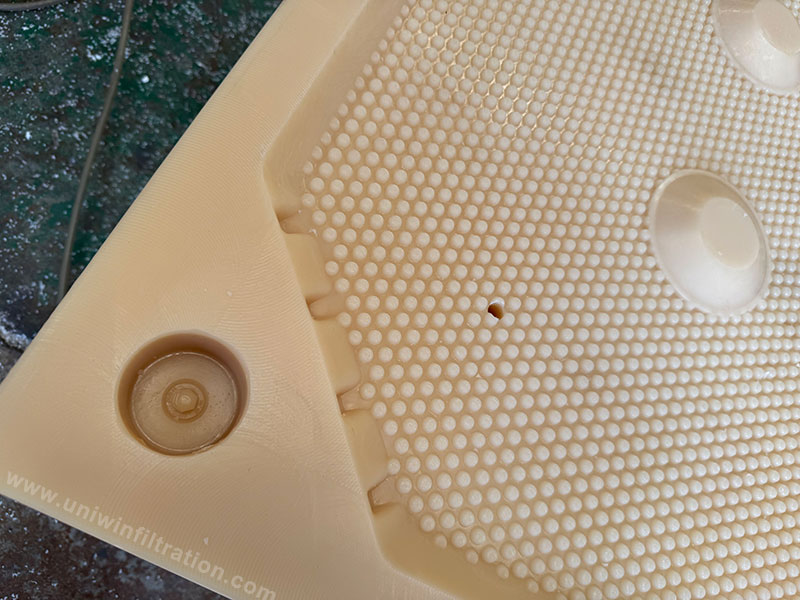

Under the alternating effects of high temperature and pressure, conventional filter plates struggle to maintain their structural strength, prone to bulging and cracking. High-temperature filter plates, however, feature a one-piece pressed structure and a thickened pressure-bearing layer, ensuring a tight seal and smoothness even under extreme operating conditions.

Improving equipment adaptability and scalability

As industrial filtration demands shift toward handling high-temperature, high-concentration, and highly corrosive materials, high-temperature filter plates can be widely used in conditions where ordinary filter plates are inadequate. This enables technological upgrades and process expansion of filter press systems, particularly in the fields of new energy and fine chemicals.

Improved economic benefits

Although the unit price of high-temperature filter plates is slightly higher, their longer replacement cycles and reduced maintenance requirements lower the overall lifecycle cost, making them suitable for businesses with high requirements for operational efficiency and reliability.

High-Temperature Filter Plate Applications

- Chemical Industry: Hot filtration of reaction solutions and pickling wastewater treatment.

- Pharmaceutical Industry: High-Temperature Sterilization and Separation of Pharmaceutical Intermediates.

- Ceramic Industry: High-Temperature Porcelain Slurry Dehydration and Ceramic Raw Material Filtration.

- Metallurgy and Minerals: High-Temperature Slurry and Flotation Tailings Dehydration.

- New Energy Industry: High-Temperature Filter Pressing and Slurry Concentration for Lithium Battery Materials.

Usage and Maintenance Recommendations

- Raise the temperature slowly when the filter is at high temperatures to avoid thermal shock.

- Regularly inspect the filter plate surface and sealing edges for signs of aging.

- Use a suitable high-temperature-resistant filter cloth.

- Prevent metallic foreign matter from scratching the filter plate surface to prevent stress concentration and cracking.