What are The Consumables of a Filter Press?

Consumables play a crucial role in the daily operation of filter presses. Components such as filter cloths, filter plates, seals, and hydraulic oil not only impact filtration performance but also directly impact equipment stability, operating efficiency, and maintenance costs. To help users better understand and select filter press consumables, this article provides a detailed introduction to common filter press consumables.

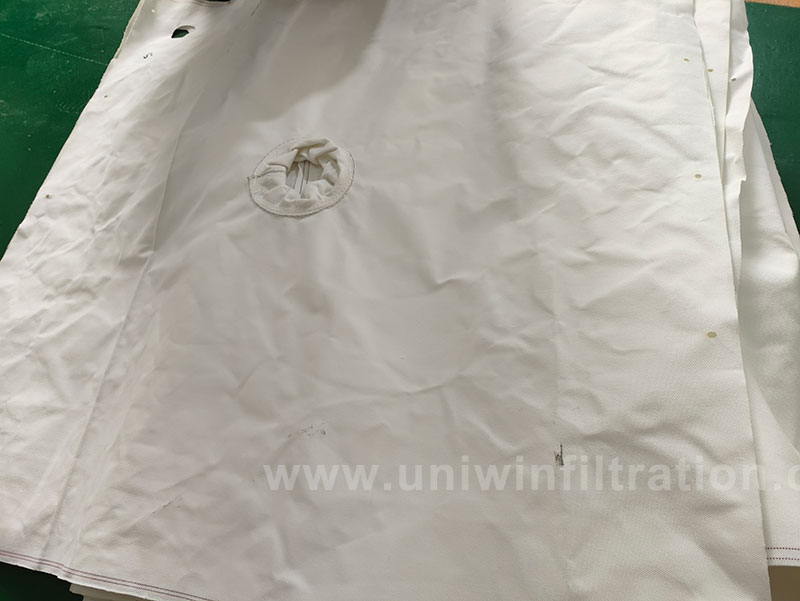

Filter Cloth

Filter cloth is an industrial filter medium, typically woven from synthetic fibers such as polypropylene, polyester, and nylon. It offers a certain level of filtration accuracy, air permeability, and tensile strength.

Common materials and types: polypropylene, polyester, nylon, double-filament, and monofilament.

Function

- It is the core filter consumable in a filter press.

- It covers each filter plate, forming a sealed filter chamber.

- It intercepts solid particles while allowing liquid to pass through, forming a filter cake.

- This determines filtration accuracy, cake thickness, moisture content, and treatment efficiency.

Filter Plates

Filter plates are rigid components that form the filter chamber within a filter press. They support the filter cloth and create a sealed space through compression, withstanding the high pressure from the hydraulic system. They are a key component of the filter press system.

Common materials: Polypropylene, cast iron, stainless steel

Function

- Combined with adjacent filter plates, they form the filter chamber, which holds the material and performs filtration.

- They provide a support surface for the filter cloth, withstand pressure, and remove the filtrate.

- Different filter plate structures (chamber type, diaphragm type) cater to different dewatering requirements.

Sealing Rings/Gaskets

Sealing rings are annular seals made of elastic material and installed in filter plates or pipe joints to prevent leakage of liquids, gases, or slurries during system operation.

Common materials: Nitrile rubber, silicone

Function

- Ensures a tight seal when the filter plates are compressed, preventing leakage of filtrate or feed.

- Maintains stable system pressure and prevents energy loss.

- Plays a critical role in protecting against high-temperature, high-pressure, or corrosive environments.

Hydraulic Oil

Hydraulic oil is a specialized transmission medium used for energy transmission, lubrication, cooling, and sealing in hydraulic systems. It offers excellent thermal stability and oxidation resistance.

Common Type: Anti-wear Hydraulic Oil

Function

- Drives the cylinder to tighten and loosen the filter plates.

- Ensures smooth system operation and provides continuous power.

- Hydraulic oil quality directly impacts equipment response speed and service life.

Hydraulic Cylinder Sealing Ring

Hydraulic cylinder seals are sealing components installed in key locations such as the piston and guide sleeve of a hydraulic cylinder to prevent hydraulic oil leakage and isolate contaminants.

Common Materials: Polyurethane, NBR Rubber

Function

- Maintains stable pressure within the hydraulic system

- Prevents hydraulic oil leakage, maintaining continuous equipment operation

- Prevents dust, moisture, and impurities from entering the cylinder, reducing wear.

Solenoid Valve Coil / Electronic Control Components

Actuators of the filter press automatic control system, including solenoid valve coils, PLC modules, sensors, relays, etc.

Function

- Controls the start and stop of hydraulic and pneumatic actuators.

- Automates filter plate pressing and unloading processes.