Common Problems and Solutions for Filter Plates

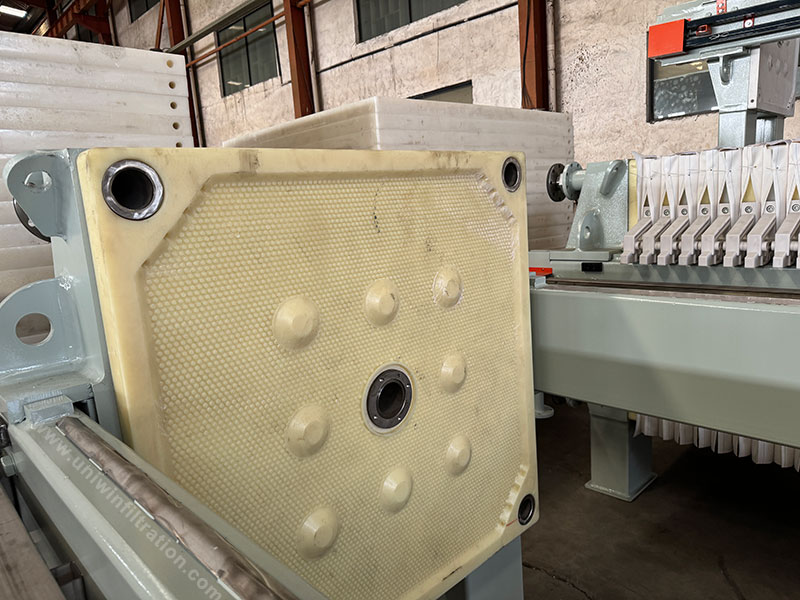

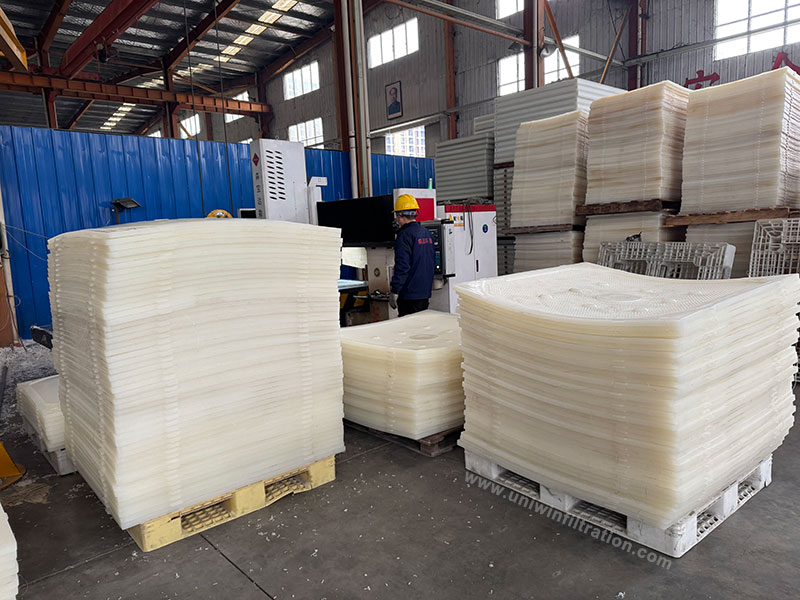

Filter press filter plates, as the core filtration component of the equipment, have a direct impact on the filtration effect and service life of the entire filter press. During long-term operation, filter plates may encounter various problems. If these problems are not detected and addressed promptly, they can easily lead to equipment failure, reduced production capacity, and even safety hazards. The following are common problems with filter press filter plates and their corresponding solutions.

Frequently Asked Questions and Root Cause Analysis

Filter Plate Rupture

Causes:

- Excessive feed pressure or frequent pressure fluctuations.

- Aging and fatigue of the filter plate material.

- Misalignment of the filter cloth or the presence of foreign objects during operation.

- Impact on the filter plate surface with hard objects during unloading.

Solutions:

- Control the pressure of the feed pump to ensure stable operation.

- Regularly replace aging filter plates; it is recommended to develop a periodic maintenance plan based on usage frequency.

- Before the operation, carefully check that the filter cloth is properly installed, avoiding wrinkles or trapped debris.

- Use soft tools for unloading; never use metal tools to strike the filter plates.

Filter Plate Leakage

Causes:

- The filter cloth is damaged or not laid flat.

- The sealing edges of the filter plate are severely worn.

- Insufficient clamping pressure on the filter plates.

Solutions:

- Replace the damaged filter cloth, ensuring it is laid flat during installation.

- Inspect the filter plate sealing surfaces; repair or replace them promptly if wear is detected.

- Check the hydraulic system pressure to ensure sufficient clamping force to seal the filter plates.

Filter Plate Deformation

Causes:

- Filter cloth blockage, leading to excessive pressure difference.

- Hard particles or foreign objects entering with the feed cause uneven stress distribution.

- The equipment is operating at high temperatures for extended periods, exceeding the filter plate’s temperature resistance limit.

Solutions:

- Keep the filter cloth clean and unobstructed; clean or replace it regularly.

- Install a pre-screening device to prevent large particles from entering the filter press chamber.

- Operate within the filter plate’s temperature resistance range; use high-temperature-resistant filter plates if necessary.

The Filter Plate is Unable to Move or is Stuck.

Reasons:

- Dust accumulation and blockage in the filter plate guide rails.

- Insufficient lubrication of the guide rails.

- Filter plate misalignment is causing mechanical interference.

Solutions:

- Regularly clean the guide rails to keep the running track clean and free of obstructions.

- Lubricate the guide rails regularly with a suitable lubricant.

- Ensure the filter plate moves centrally during operation to avoid off-center loading.

Preventive Measures

- Standardize operating procedures: Train operators and ensure they strictly follow the equipment manual.

- Regular inspection and maintenance: Develop a periodic plan for filter plate inspection, replacement, and equipment maintenance.

- Use compliant parts: Select high-quality filter plates and filter cloths that match the filter press model, avoiding the use of inferior materials.

- Optimize process parameters: Maintain parameters such as feed concentration, flow rate, and pressure within the recommended range to reduce impact and wear on the filter plates.

Conclusion

Although filter plate problems are common, most can be avoided or quickly resolved through proper maintenance and operating procedures. Emphasis should be placed on daily inspection and maintenance of filter plates, and a comprehensive equipment management system should be established to ensure the efficient and stable operation of the filter press, extend equipment lifespan, and ultimately improve overall production efficiency.