Filter Press Installation and Commissioning

Filter press installation and commissioning are critical steps to ensure safe operation and efficient dewatering performance. The following is a detailed step-by-step guide, covering the entire process from equipment arrival to commissioning, to help users standardize operation, extend equipment life, and improve efficiency.

Filter Press Installation Steps

Pre-Installation Preparation

- Carefully read the equipment manual, foundation drawings, electrical drawings, and hydraulic system diagrams. Confirm that the filter press model, specifications, and installation dimensions match the site space.

- Inspect the main unit, hydraulic station, electrical control cabinet, filter plates, filter cloth, and related accessories. Check for transport damage, missing parts, or rust.

- Construct according to the foundation drawings provided by the filter press manufacturer, ensuring the foundation is level, secure, and has sufficient load-bearing capacity.

- Ensure the installation site is well ventilated and the ground is flat to facilitate subsequent drainage and maintenance.

Main Equipment Installation

Lifting the main unit

Use a crane to remove the main unit from the transport vehicle. Lift the unit from the designated lifting eyes at each end of the main beam. Do not hang it from the filter plates or oil cylinder. Keep the unit level to prevent deformation of the main beam or filter plates.

Positioning and leveling

Place the filter press on the foundation and accurately align it according to the centerline and reference points. Use a spirit level to check that the main beam is level.

Securing the filter press

Align the anchor holes on the foundation and insert the anchor bolts. Tighten the anchor nuts evenly to ensure the filter press is stable and does not wobble.

Auxiliary System Installation

Hydraulic System Installation

- Locate the hydraulic pump station to the side or rear of the main engine for easy connection and maintenance.

- Connect the hydraulic oil pipes and high-pressure oil pipes connecting the cylinders to the pump station. Use sealant or sealing rings at all joints to prevent leaks.

- Fill the tank with the specified hydraulic oil. Check the oil level and filter for cleanliness.

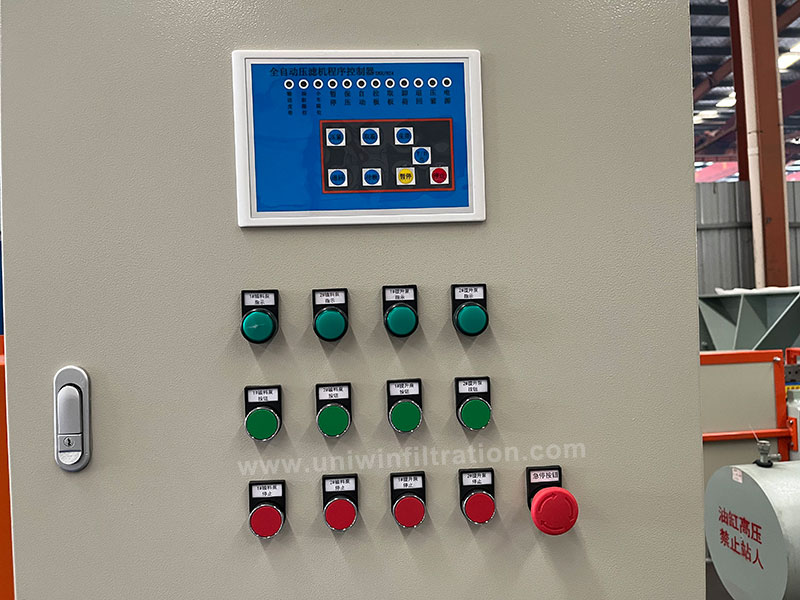

Electrical Control System Installation

- Place the electrical control cabinet in a dry, safe, and easily accessible location.

- Connect the power cables, signal cables, and actuators.

- All cables should be clearly numbered, neatly routed, and securely connected.

- The ground wire must be securely connected to a ground to prevent static electricity and electrical leakage.

Pipeline Connections

- Feed pipeline: connects the feed pump outlet to the filter press inlet. Pressure-resistant and corrosion-resistant flange connections are recommended.

- Discharge pipeline: collects the liquid from each filter plate outlet to a sump or drainage system.

- Washing pipeline: connects to the filter press cloth wash nozzle or filter cloth backwash system.

- Air blowing pipeline: install an air compressor and air blower valve, and check the stability of the air source.

Filter Press Commissioning Steps

No-Load Commissioning

Check the electrical system. Before applying power, confirm that the wiring is correctly connected and that all buttons and indicators are functioning properly.

Trial Run

- Start the main unit and observe whether the filter plates advance and retract smoothly.

- Check the hydraulic system for stable pressure and leaks.

- Check the pneumatic components (such as the clamping cylinder and air blower system) for proper operation.

Load Testing

- Add material for a pressure test. Use a low-concentration slurry for the initial pressure test. Observe the filter cake formation and ensure the filter cloth is laid flat, without folds or deviations.

- The filter cloth must fit snugly on the filter plates and must be free of wrinkles, which will affect the dewatering effect.

- Check that the outlet holes on each filter plate are unobstructed. Check for any abnormalities such as leaks and spraying.

Performance Verification

- Test a complete filter press cycle (pressing → feeding → holding pressure → unloading → opening the filter).

- Record time and capacity data as a baseline for operating parameters.

Safety Protection Test

- Check whether the emergency stop button is functional.

- Check whether the limit switches and pressure protection devices are sensitive and reliable.

Operating Precautions

- Initial commissioning should be performed under the guidance of a professional or in cooperation with the manufacturer’s technical staff.

- Before use, operators should receive systematic training to familiarize themselves with the equipment’s structure and operating procedures.

- Regularly inspect vulnerable components such as the hydraulic oil, filter cloth, and seals to ensure long-term stable operation of the equipment.