How to Improve Filter Cake Dryness?

In the field of solid-liquid separation, filter cake dryness (i.e., moisture content) is an important indicator of the quality of the filtration process. Higher dryness not only reduces subsequent drying or transportation costs but also improves product purity and reduces the burden of wastewater treatment. In industries such as mining, chemical engineering, environmental protection, and food processing, improving filter cake dryness is a key step in enhancing overall process efficiency.

This article introduces the primary factors influencing the dryness of filter cakes and presents a comprehensive optimization approach that combines advanced process techniques, including filter cake washing, diaphragm pressing, and blow-drying technology.

Increasing Filtration Pressure and Optimizing Filtration Cycles

Higher feed pressure can force the liquid through the filter cloth more quickly, resulting in a denser filter cake with lower moisture content. Typical feed pressure for filter presses is 0.6 MPa, while high-pressure models can reach 1.2 MPa, but the pressure resistance of the equipment and piping must be ensured.

Within a suitable range, appropriately extending the pressure-holding time during the filtration cycle helps to further squeeze out the liquid and achieve more thorough dewatering of the filter cake.

Selecting the Appropriate Filter Cloth Type and Structure

The choice of filter cloth directly affects the filtration speed and the dewatering performance of the filter cake.

- Material recommendation: Polypropylene filter cloth is resistant to acids and alkalis, wear-resistant, and has good dewatering performance.

- Pore size matching: Too large a pore size can lead to fine particles passing through, while too small a pore size can easily cause clogging. The pore size should be precisely matched to the particle size of the material.

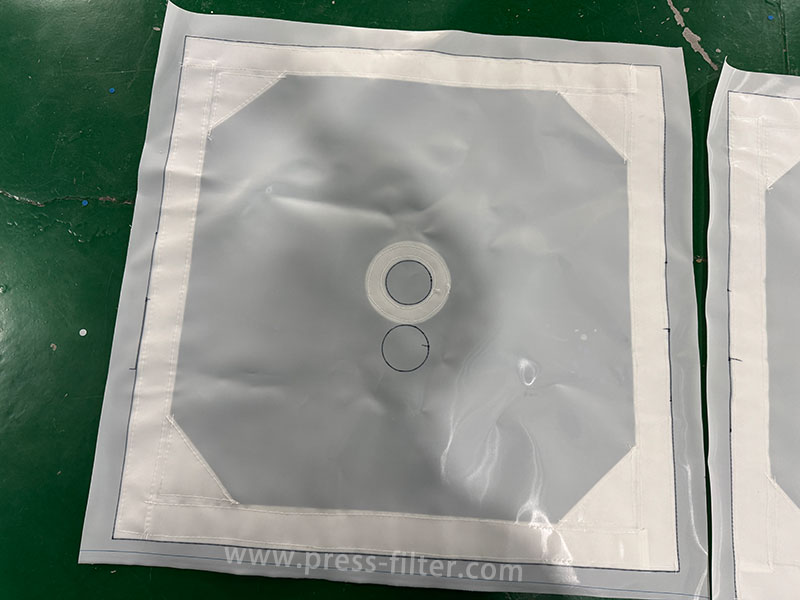

Introduction of Diaphragm Pressing Technology (Secondary Pressing)

Working Principle

After the main filtration is completed, the diaphragm in the filter plate (made of rubber or polypropylene) is inflated with air or water, causing it to expand and press the filter cake, thereby squeezing out more water. This further reduces the moisture content of the filter cake.

Filter Cake Washing

Washing objectives:

- To remove residual mother liquor (such as acids, bases, salts, solvents, etc.).

- To improve product purity.

- To reduce wastewater load and indirectly facilitate dewatering.

Through washing, the high-viscosity or high-concentration residual liquid in the filter cake is replaced by clean water, making it easier to remove during subsequent pressing or drying, thus improving overall dryness.

Implementing the Filter Cake Drying Process

Drying Principle

After filtration is complete, dry compressed air is introduced, creating an airflow path through the filter cake to expel or remove residual moisture from within the filter cake.

Function:

- After blow-drying, the moisture content of the filter cake can be significantly reduced.

- It can replace part of the thermal drying process, saving energy and reducing costs.

- When combined with diaphragm pressing and filter cake washing, the degree of dryness can be further improved.

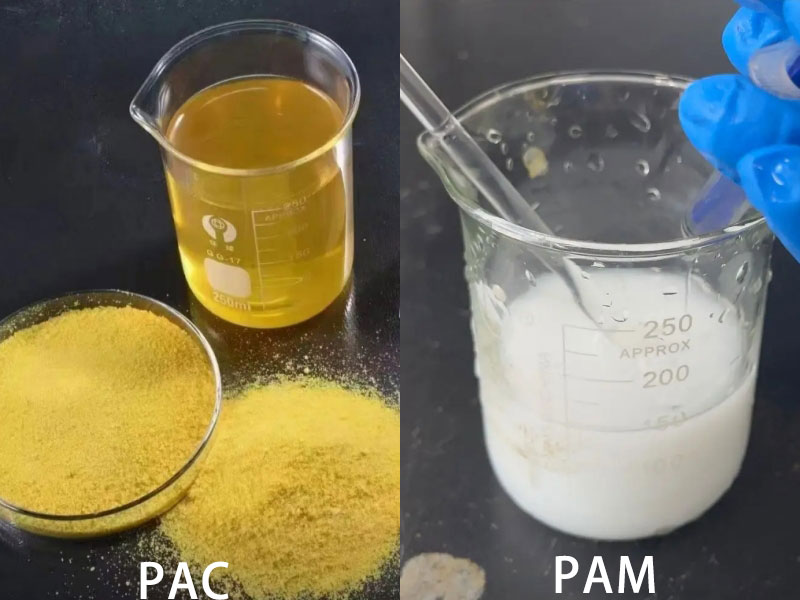

Optimizing Material Conditions

Improving filter cake dryness depends not only on the equipment but also on controlling the slurry state.

- Adding flocculants (such as PAM, PAC): Improves particle aggregation and filtration performance.

- Controlling feed concentration and temperature: Appropriately increasing the temperature can reduce the viscosity of the filtrate, which is beneficial for water removal.

- pH adjustment: Some materials exhibit better settling properties at a specific pH, which facilitates filter pressing.

Intelligent Control

Introduces an automatic detection and feedback system to adjust pressure, flow rate, and time in real time.

Uses a PLC control system to automatically switch between “filtration-pressing-washing-drying” modes, improving overall operating efficiency.

Conclusion

Through the measures described above, the dryness of the filter cake can be significantly improved, the production process can be optimized, and energy consumption can be reduced. If you wish to customize a filter press system or upgrade solution based on specific process scenarios (such as mineral processing, sludge treatment, etc.), please provide us with your material parameters, and we will tailor a recommendation for you.