Plate and Frame Filter Press VS Chamber Filter Press

Plate and frame filter presses and chamber filter presses are two common types of solid-liquid separation equipment. Although their principles are similar—both utilize filter plates and filter cloths to separate solids and liquids from a mixture—they differ significantly in structure, operation, applicable scenarios, and performance. The following is a detailed comparison of the two.

Structure and Working Principle

The plate and frame filter press uses a combination of solid filter plates and hollow filter frames. The filter plates and frames are arranged alternately, and when clamped together, they form filter chambers in the middle. The filtrate passes through the filter cloth, while the solids remain in the filter chambers, forming a filter cake. Its structure is relatively traditional; disassembling and assembling the filter plates requires individual handling, and it cannot be equipped with automatic plate pulling, making the operation process largely manual.

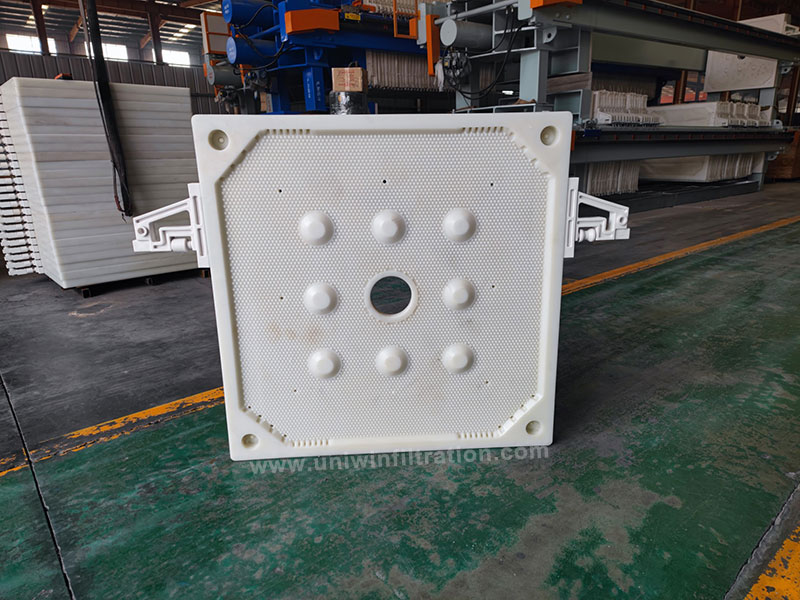

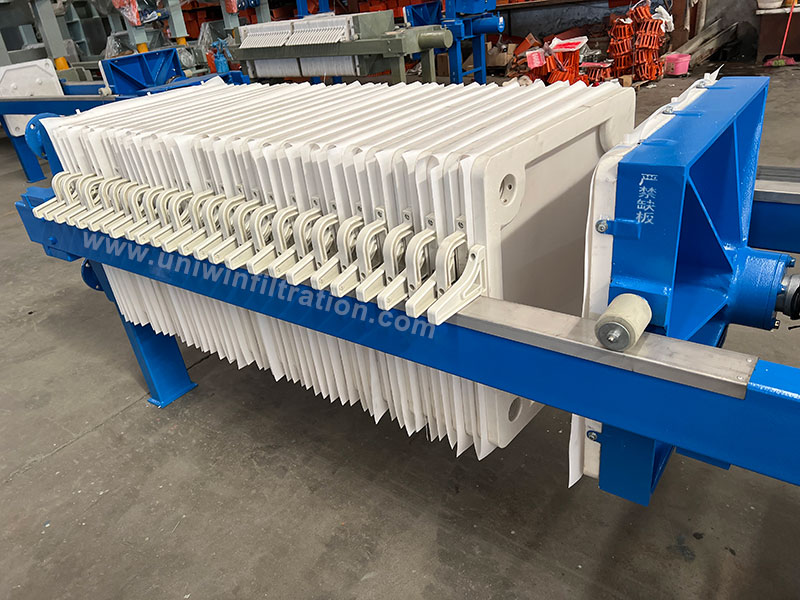

Recessed filter presses, on the other hand, consist of two identical solid filter plates with recessed surfaces. Each pair of plates, when closed together, forms a sealed filtration chamber. This structure is more compact, offers better sealing performance, and is suitable for automated operation, effectively improving filtration efficiency and operational safety.

Filtration Efficiency and Filter Cake Dryness

In terms of filtration efficiency and filter cake dryness, plate-and-frame filter presses are generally inferior to chamber filter presses. Their dewatering process primarily relies on initial filtration pressure and lacks effective subsequent pressing mechanisms. Due to the deep filter frames, the drainage path in the middle of the filter cake is long, resulting in insufficient dewatering. In practical operation, the moisture content of the filter cake is often high, and the filtration cycle is longer, leading to relatively lower overall efficiency.

Chamber filter presses offer superior filtration efficiency and dewatering performance. Their filter chambers are formed by the closure of two filter plates, resulting in a uniform structure that allows for more thorough dewatering under the same pressure conditions. Furthermore, a recessed chamber can be equipped with enhanced dewatering processes such as diaphragm pressing, air drying, or water washing, significantly reducing the moisture content of the filter cake while shortening the filtration cycle.

Ease of Operation and Level of Automation

In terms of operation, plate-and-frame filter presses are mostly semi-automatic or manually operated, especially during the cake discharge process, which requires manual removal of each filter plate, resulting in high labor intensity and low efficiency.

Chamber filter presses, on the other hand, generally feature automatic plate pulling, automatic discharge, and automatic cleaning functions, enabling fully automatic operation. This significantly reduces manual involvement, improving overall production efficiency and operational safety.

Sealing Performance and Applicability

Due to structural differences, the sealing of plate-and-frame filter presses relies on the edging and compression force of the filter cloth, which can easily lead to leakage after long-term use.

In contrast, chamber filter presses have better sealing performance. The hydraulic compression creates a more stable sealed space, offering stronger pressure resistance and corrosion resistance, making them suitable for industries with high demands on sealing performance.

Maintenance Costs and Service Life

Due to its loose structure, plate-and-frame filter presses require frequent replacement of filter cloths, and the filter plates are prone to damage during disassembly and assembly, resulting in relatively high maintenance costs, especially in continuous operation environments.

Chamber plate filter presses, with their highly integrated structure, fixed filter cloths, and minimal wear on the filter plates, coupled with an automatic cleaning system, effectively reduce maintenance frequency and manual intervention. Their equipment stability and service life are generally superior to plate-and-frame types.

Concluison

In summary, both plate and frame filter presses and chamber filter presses have their own advantages. When selecting a model, it is recommended to consider factors such as material characteristics, processing capacity requirements, operating cycle, and budget. If you have any specific needs, please feel free to contact us for further discussion; we can provide customized solutions.