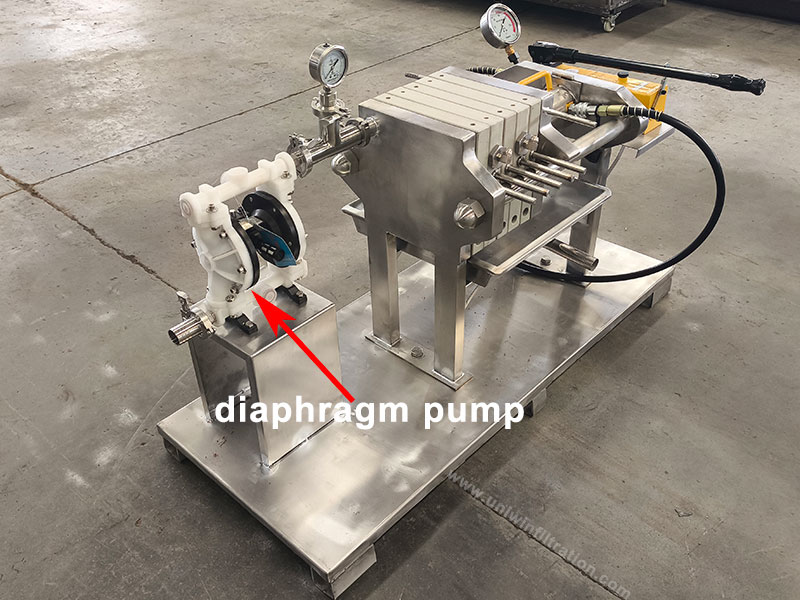

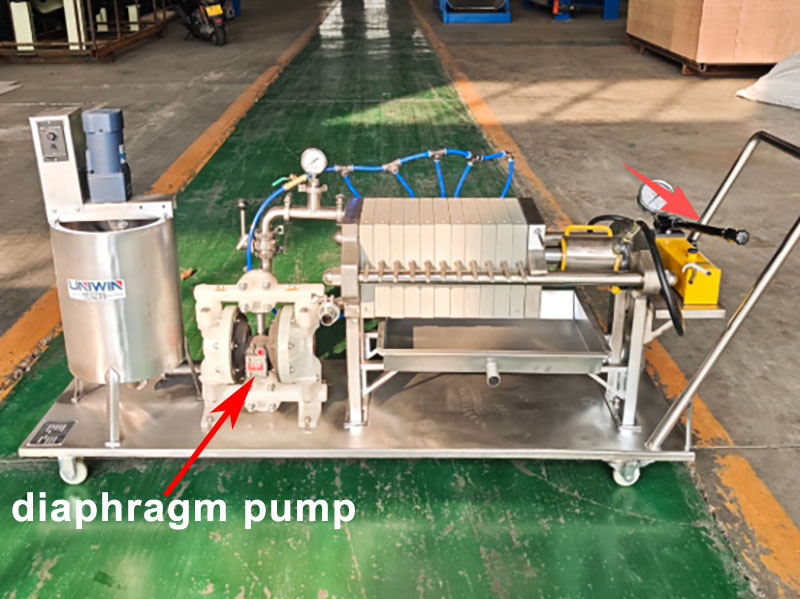

Diaphragm Pump

The diaphragm pump is one of the key feeding devices in a filter press system, mainly used to transport slurries (such as sludge, mineral slurry, chemical slurry, etc.) into the filter chamber of the filter press. It is widely used in various solid-liquid separation processes due to its simple structure, strong adaptability, strong self-priming ability, and ability to handle high-viscosity, high-solids-content materials.

Working Principle of a Diaphragm Pump in a Filter Press

A diaphragm pump is a positive displacement pump that uses reciprocating motion to change the volume of a chamber, thereby drawing in and discharging liquid. Its core component is the diaphragm, which reciprocates under the action of a drive unit (pneumatic or electric) to draw in or discharge material.

In a filter press system, the diaphragm pump typically works in conjunction with a pressure control device. When the pressure inside the filter chamber increases, the pump’s output pressure increases synchronously to meet the high-pressure requirements of the filtration and dewatering process.

Diaphragm Pump Parameter

| Model | Flow(m 3 /h) | Lift(m) | Outlet pressure(kgf/cm 2) | suction lift(m) | Allowable particle diameter(mm) | Air supply pressure(kbf/cm 2) | Air supply consumption(m 3 /min) |

|---|---|---|---|---|---|---|---|

| QBY-10 | 0~0.8 | 0~50 | 5 | 5 | 1 | 7 | 0.3 |

| QBY-15 | 0~1 | 0~50 | 5 | 5 | 1 | 7 | 0.3 |

| QBY-25 | 0~2.4 | 0~50 | 5 | 7 | 2.5 | 7 | 0.6 |

| QBY-40 | 0~8 | 0~50 | 5 | 7 | 4.5 | 7 | 0.6 |

| QBY-50 | 0~12 | 0~50 | 5 | 7 | 8 | 7 | 0.9 |

| QBY-65 | 0~16 | 0~50 | 5 | 7 | 8 | 7 | 0.9 |

| QBY-80 | 0~24 | 0~50 | 5 | 7 | 10 | 7 | 1.5 |

| QBY-100 | 0~30 | 0~50 | 5 | 7 | 10 | 7 | 1.5 |

Advantages of Diaphragm Pumps in Filtration Systems

Strong self-priming capability

Diaphragm pumps have a strong self-priming function, allowing materials to be drawn into the pump body without priming, making them easy to start. Compared to centrifugal pumps, they do not require priming or the installation of a foot valve, making them suitable for intermittent or mobile operations.

Capable of conveying high-viscosity media containing solid particles

Diaphragm pumps are suitable for conveying high-viscosity fluids containing particles or corrosive substances; they have a strong ability to handle large particles and are not prone to jamming or wear like centrifugal or gear pumps.

No mechanical seal, no leakage risk

The diaphragm completely isolates the medium from the drive mechanism, avoiding pump leakage problems; it is particularly suitable for conveying toxic, volatile, and corrosive liquids, such as acids, alkalis, oils, and organic solvents.

Can operate under no-load conditions

The pneumatic diaphragm pump can run dry for short periods without burning out due to a lack of liquid, unlike other pumps; it is suitable for unstable feeding conditions in harsh environments.

Simple operation and low maintenance costs

Compact structure, easy disassembly and assembly, and easy maintenance; the core wear component is the diaphragm, which can be replaced periodically, resulting in low operating costs.

Adjustable pressure and flow

The pneumatic type allows for flexible control of output pressure and flow by adjusting the inlet air pressure.

Wide range of applications

It can transport acids, alkalis, solvents, oils, water, slurries, etc.; it can adapt to extreme working conditions such as high temperature, low temperature, high corrosiveness, and strong abrasion.

High explosion-proof safety (pneumatic type)

The pneumatic diaphragm pump does not use electricity, eliminating the risk of sparks and making it ideal for explosion-proof environments such as chemical plants and paint shops.

High compatibility

It has a high compatibility with filter presses, enabling high-pressure feeding and effectively improving the dryness of the filter cake.

Precautions for Use

- Select the right model: Choose the model based on parameters such as slurry properties, working pressure, and flow rate.

- Regularly inspect the diaphragm: The diaphragm is a wear part and needs to be inspected and replaced regularly during use.

- Avoid prolonged dry runs: Although diaphragm pumps can run dry for short periods, prolonged dry runs will cause diaphragm wear.

- Properly adjust air pressure or voltage: Ensure the pump operates under appropriate load conditions to avoid damage caused by excessive pressure.

- Stable installation: The inlet and outlet ports must be well supported to prevent vibration from affecting the pump’s lifespan.