Filter Plate of Filter Press

The filter plate is one of the core components of the filter press and bears the key function of solid-liquid separation. The performance and type of the filter plate directly affect the filtration effect, processing efficiency, and equipment life. According to the different structural forms, material composition, and applicable environment, the filter plate can be divided into many types. The following are several common and widely used filter plate types.

Plate and Frame Filter Plate

Structural features: It is composed of alternating solid plates and hollow frames, and the filter cloth is sandwiched between the plates and the frames.

Scope of application: It is suitable for medium and low pressure conditions, and is suitable for processing materials with low viscosity and coarse solid particles.

Advantages:

- Simple structure, easy to disassemble and clean;

- Relatively low cost;

- Suitable for use in laboratories or small and medium-sized enterprises.

Disadvantages:

- Filter residue is easy to leak.

- The filtration efficiency is relatively low.

- Cannot withstand high-pressure operation.

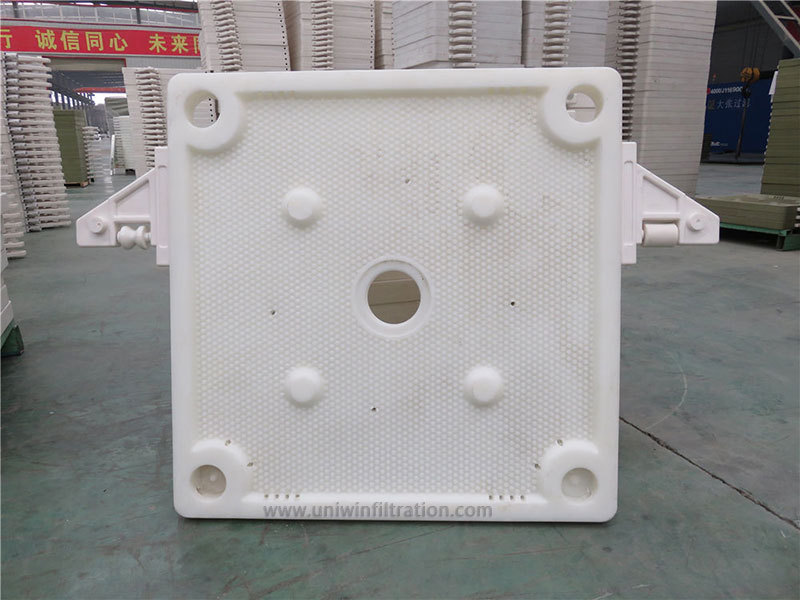

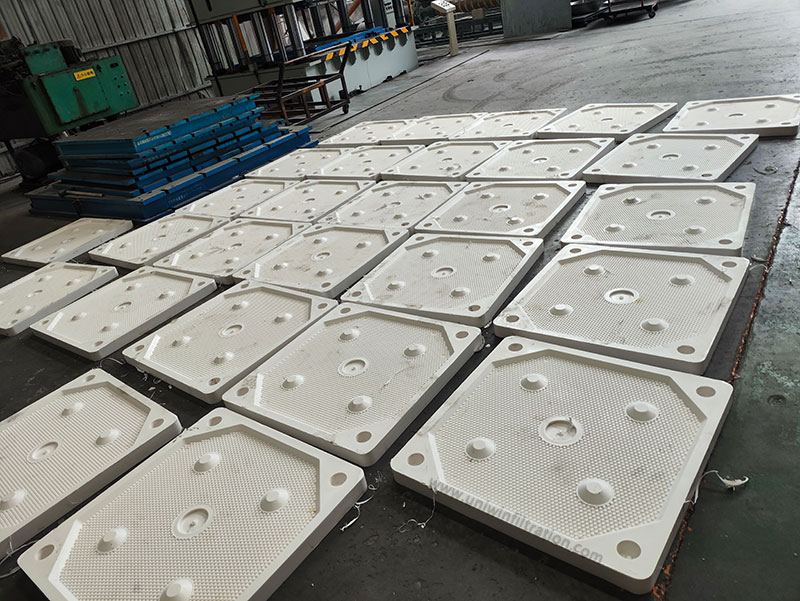

Chamber Filter Plate

Structural features: The middle of the plate surface is concave, and the filter plates form an independent and closed filter chamber.

Scope of application: Widely used in chemical, pharmaceutical, food, environmental protection, and other industries.

Advantages:

- Good sealing performance;

- High degree of automation;

- Easy to operate and maintain.

Disadvantages:

- The moisture content of the filter cake is relatively high.

- The cost of the filter plate is slightly higher than that of the plate and frame type.

Diaphragm Filter Plate

Structural features: Add an expandable elastic membrane layer (usually a rubber or polypropylene membrane) to the ordinary chamber filter plate, and achieve secondary squeezing through compressed air or hydraulic medium.

Scope of application: Applicable to processes that require extremely low filter cake moisture content, such as sludge dehydration, fine chemicals, and other fields.

Advantages:

- The filter cake has a low moisture content, saving subsequent drying costs;

- The secondary squeezing function improves dehydration efficiency.

- Suitable for continuous and efficient production.

Disadvantages:

- Complex structure and high cost;

- High requirements for the operating system.

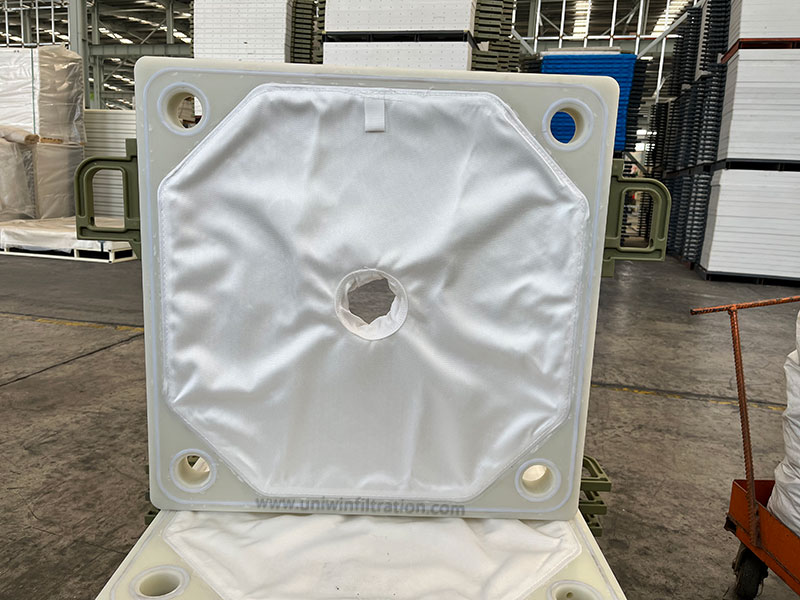

Gasketed Filter Plate

Structural features: The gasketed filter plate is a filter cloth with a fixing slot reserved on the surface of the filter plate, and the edge of the filter cloth is embedded in the filter plate, so as to form a tightly sealed, neat, and uniform filtering interface. The filter cloth is almost flush with the surface of the filter plate, and the traditional cloth clamping or external hanging structure is no longer used.

Scope of application: Suitable for scenes with high requirements for sealing, automatic cleaning, and hygiene level.

Advantages:

- Stronger sealing;

- Easy to clean, no protruding filter cloth, smooth surface;

- The filter cloth is more stable, the filter cloth is firmly fixed, and it is not easy to move or bulge.

Disadvantages:

- Complicated replacement of filter cloth;

- High initial cost;

- High requirements for filter cloth customization.

Cast Iron Filter Plate

Structural features: Made of cast iron, one-piece molding, with extremely strong mechanical strength.

Scope of application: Suitable for processing materials with low acidity and alkalinity and low temperature.

Advantages:

- Strong structure and good wear resistance;

- Long service life.

Disadvantages:

- Heavy and inconvenient to carry;

- Not suitable for high temperature or highly corrosive media.

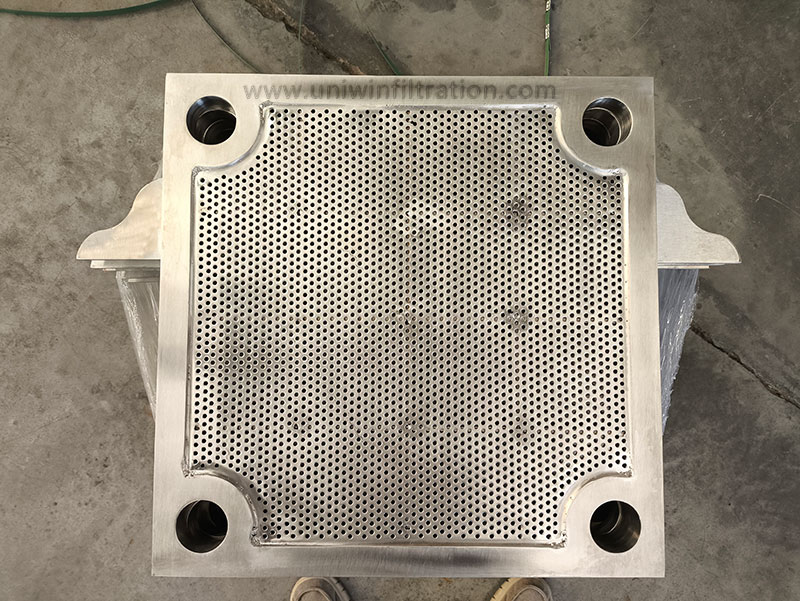

Stainless Steel Filter Plate

Structural features: Made of 304, 316L, and other stainless steel materials, it has strong corrosion resistance.

Scope of application: Applicable to industries with high requirements for hygiene or corrosion, such as food, pharmaceuticals, and chemicals.

Advantages:

- Acid and alkali corrosion resistance;

- Easy to clean and disinfect;

- Long service life.

Disadvantages:

- High cost;

- Complex processing.

Round High-Pressure Filter Plate

Structural features: The round structure is reinforced and made of high-strength materials, which can withstand high-pressure operation.

Scope of application: Suitable for processing materials with high viscosity, high solid content or deep dehydration.

Advantages:

- High compaction of filter cake.

- Clearer filtrate;

- Improve unit output efficiency.

Disadvantages:

- High requirements for the overall structure of the filter press;

- Pay attention to safety control during operation.

High Temperature Filter Plate

Structural features: high-temperature-resistant materials (using a special formula) can operate for a long time in a high-temperature environment.

Scope of application: suitable for processing high-temperature slurry, such as metallurgy, battery materials, the chemical industry, and other industries.

Advantages:

- It can withstand high temperatures.

- Not easy to deform, strong chemical stability.

- Safe and reliable to use.

Disadvantages:

- High cost.

- Limited material selection.