Filter Press Sealing Strips

Filter press sealing strips are one of the key sealing components of a filter press. Their main function is to prevent leakage of liquid and sludge from the filter chamber during the pressing process. Their quality is closely related to the sealing performance, working efficiency, and service life of the filter press.

Common Sealing Strip Materials

- Rubber: Good elasticity, suitable for neutral or weakly acidic/alkaline media, such as municipal sewage and domestic sludge.

- Fluororubber: High temperature and strong corrosion resistance, suitable for the chemical and pharmaceutical industries.

- Polytetrafluoroethylene (PTFE): Extremely high chemical stability, resistant to almost all chemical media, suitable for strong acid and strong alkali environments, and special working conditions.

- Polyurethane: High strength and excellent wear resistance, suitable for high-pressure environments and slurry filtration.

Advantages of Using Sealing Strips

- Enhanced sealing effect

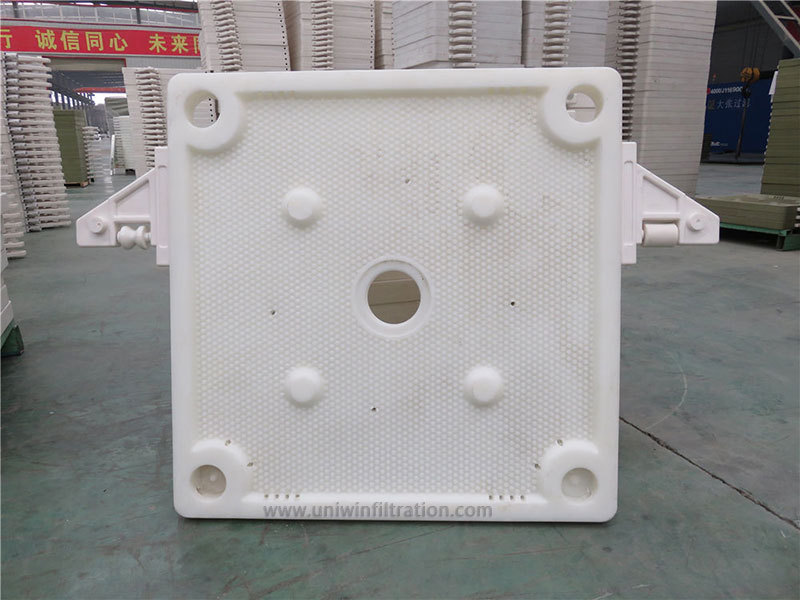

The sealing strips are embedded in the grooves on the edges of the filter plates. As the filter plates are pressed together, the sealing strips are compressed, effectively preventing filtrate leakage between the filter plates and ensuring the sealing integrity of the filtration chamber. - Prevention of displacement and falling off

The embedded structure securely fixes the sealing strips, preventing them from falling off or shifting during frequent opening and closing operations, thus improving operational stability and safety. - Suitable for high-pressure filtration environments

The sealing structure at the edges of the filter plates maintains excellent contact even under high pressure, allowing it to withstand higher filtration pressures. - Easier maintenance

The embedded sealing strips are easy to replace, requiring no complete disassembly of the machine; only the corresponding filter plate needs to be removed to replace damaged seals.

Usage and Maintenance Recommendations:

- Regularly check the sealing strips for signs of aging or cracking.

- Each time the filter cloth is replaced, also check if the sealing strips are displaced or damaged.

- Select sealing strip materials suitable for the operating conditions to prevent sealing failure due to incompatible materials.

- Avoid misalignment of the filter plates during compression to prevent damage to the sealing strips.