Plate and Frame Filter Press

The plate and frame filter press is a widely used device for solid-liquid separation. As its name implies, it consists of alternating plates and frames that form enclosed filter chambers. This equipment finds broad applications across industries such as chemicals, pharmaceuticals, food processing, metallurgy, and environmental protection. Its working principle is to use the filter plate and the filter frame to alternately arrange to form a filter chamber and squeeze out the liquid part of the slurry by pressurization to achieve solid-liquid separation.

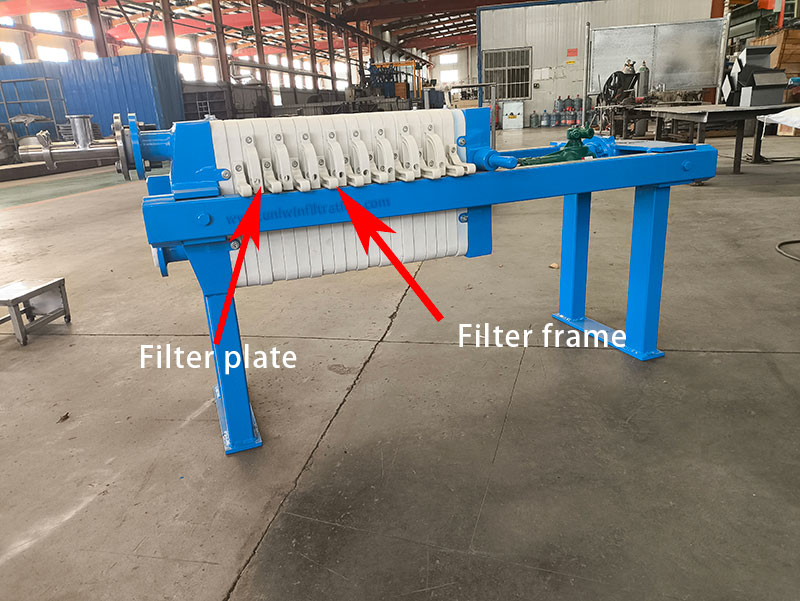

Structural Composition of Plate and Frame Filter Press

Filter plate and filter frame

The filter plate is usually made of high-strength polypropylene or cast iron, with grooves on the surface to support the filter cloth. The filter frame is used to carry the filter residue. The filter plates and frames are arranged in an alternating sequence to create individual filter chambers.

Filter cloth

The filter medium, installed on the filter plate, is used to intercept solid particles (i.e., filter cake).

Compression Device

It is available in three types—manual, hydraulic, and mechanical. Its function is to press the filter plate and the filter frame tightly to squeeze out the excess water in the material, thereby forming a dry filter cake to ensure high filtration efficiency.

Feeding system

The slurry is delivered to each filter chamber of the filter press by the feed pump and distributed evenly throughout. After the feeding is completed, the filtration begins.

Drainage system

Each filter plate of the open-flow filter press has a liquid outlet valve to discharge the filtered water, while the hidden-flow filter press has a liquid outlet valve at the end to discharge the filtrate centrally.

Brief Description of Working Principle

- The filter plate and filter frame form a sealed filter chamber under the action of the clamping device.

- The feed pump injects the slurry into the filter chamber.

- Under pressure, the liquid passes through the filter cloth, while the solids are retained on its surface, forming a filter cake.

- After the filtration is completed, the filter frame is removed, and the filter cake is removed manually or mechanically.

Plate and Frame Filter Press Parameters

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number plate(pcs) | Filtration pressure(Mpa) | Motor power(KW) | Weight(KG) | DimensionsL*W*H(mm) |

|---|---|---|---|---|---|---|---|---|---|

| BMY4/450-30U | 4 | 500*500 | 30 | 60 | 9 | ≤0.6 | 2.2 | 860 | 1950*700*900 |

| BMY6/450-30U | 6 | 91 | 14 | 910 | 2200*700*900 | ||||

| BMY8/450-30U | 8 | 121 | 19 | 960 | 2450*700*900 | ||||

| BMY15/630-30U | 15 | 700*700 | 226 | 18 | 1725 | 2640*900*1100 | |||

| BMY20/630-30U | 20 | 297 | 24 | 1993 | 2940*900*1100 | ||||

| BMY30/630-30U | 30 | 452 | 37 | 2360 | 3590*900*1100 | ||||

| BMY40/630-30U | 40 | 595 | 49 | 2788 | 4300*900*1100 | ||||

| BMY30/870-30U | 30 | 870*870 | 460 | 23 | 2580 | 3330*1400*1300 | |||

| BMY50/870-30U | 50 | 748 | 38 | 3318 | 4260*1400*1300 | ||||

| BMY60/870-30U | 60 | 902 | 46 | 3712 | 4700*1400*1300 | ||||

| BMY80/870-30U | 80 | 1210 | 62 | 4561 | 5580*1400*1300 | ||||

| BMY80/1000-30U | 80 | 1193 | 46 | 5259 | 5120*1500*1400 | ||||

| BMY100/1000-30U | 100 | 1473 | 57 | 5985 | 5800*1500*1400 | ||||

| BMY120/1000-30U | 120 | 1777 | 69 | 6776 | 6500*1500*1400 | ||||

| BMY100/1250-30U | 100 | 1250*1250 | 1468 | 36 | 6728 | 5020*1770*1600 | |||

| BMY160/1250-30U | 160 | 2341 | 58 | 8205 | 6450*1770*1600 | ||||

| BMY200/1250-30U | 200 | 2896 | 72 | 10851 | 7360*1770*1600 | ||||

| BMY250/1250-30U | 250 | 3650 | 91 | 12834 | 8600*1770*1600 | ||||

| BMY300/1500-30U | 300 | 1500*1500 | 5235 | 74 | 25526 | 8130*2200*1900 | |||

| BMY400/1500-30U | 400 | 6985 | 99 | 32074 | 9880*2200*1900 | ||||

| BMY500/1500-30U | 500 | 8735 | 123 | 38106 | 11560*2200*1900 |

Unique Advantages of Plate and Frame Filter Press

High filtration accuracy, suitable for fine separation

The filter chamber structure of the plate and frame filter press is relatively flexible, and the appropriate filter cloth can be selected according to the properties of the material, so that it performs well when processing high viscosity, fine particles, or materials with high filtration accuracy requirements.

Simple structure and low cost

Compared with chamber filter presses and diaphragm filter presses with complex structures and high automation, plate and frame filter presses have simpler structures and are easier to maintain. The initial investment cost is relatively low, especially suitable for small and medium-sized enterprises or experimental conditions.

Strong adaptability and flexible operation

The filter plate and filter frame can be combined and adjusted according to the working conditions, and the filter chamber volume can be changed to meet the processing requirements of different materials and batches. A variety of filter cloth materials and filter pressure combinations can be achieved, and the adaptability is far beyond the general belt filter press.

Suitable for intermittent operation, easy to control batch quality

The plate and frame filter press is essentially an intermittent operation, suitable for industries such as fine chemicals and pharmaceuticals that have strict quality control for each batch. Parameters can be adjusted in time according to the status of each batch of materials to achieve higher process flexibility.

However, one drawback of the plate and frame filter press is its lower level of automation compared to other types of filter presses.