Vacuum Belt Filter

Vacuum belt filter is a continuously operated solid-liquid separation equipment, widely used in chemical, metallurgical, mining, pharmaceutical, environmental protection, and other industries. Its core advantages are continuous operation, high filtration efficiency, and suitability for large-volume slurry processing.

The Structure of The Vacuum Belt Filter

- Filter cloth: filter medium, which needs to be selected according to the properties of the material.

- Rubber belt: supports the filter cloth and has a vacuum channel.

- Vacuum box: provides a negative pressure environment.

- Distribution head: distributes vacuum to each section.

- Correcting device: uses a cylinder or airbag to push the corrective rotation to a certain angle to automatically correct the deviation of the filter cloth and ensure the normal operation of the filter cloth.

- Washing system: multi-section spray pipes are used for filter cake washing.

- Drive system: motor + reducer drives the whole machine to operate.

- Control system: PLC automatically controls the operating parameters.

Structurally, the filter sections are arranged along the horizontal length direction, and can continuously and automatically complete the process operations such as filtration, filter cake washing, slag unloading, filter cloth regeneration, etc., and the mother liquor and filter cake washing liquid can be collected in sections. It has the advantages of high filtration efficiency, large production capacity, and simple maintenance.

Vacuum Belt Filter Parameters

| Belt Width | 1000mm | 1500mm | 2000mm | 2500mm | 3000mm | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Length (mm) | Filtering Area | Weight (kg) | Filtering Area | Weight (kg) | Filtering Area | Weight (kg) | Filtering Area | Weight (kg) | Filtering Area | Weight (kg) |

| 3000 | 3 | 3700 | 4.5 | 4300 | 6 | 4900 | 7.5 | 5700 | 9 | 6300 |

| 4500 | 4.5 | 3890 | 6.75 | 4525 | 9 | 5160 | 11.25 | 6000 | 13.5 | 6640 |

| 6000 | 6 | 4080 | 8 | 4750 | 12 | 5420 | 15 | 6300 | 18 | 6980 |

| 7500 | 7.5 | 4270 | 11.25 | 4900 | 15 | 5680 | 18.75 | 6600 | 22.5 | 7320 |

| 9000 | 9 | 4460 | 13.5 | 5050 | 18 | 5940 | 22.5 | 6900 | 22.5 | 7320 |

| 10500 | 10.5 | 4650 | 14.75 | 5275 | 21 | 6200 | 26.25 | 7200 | 31.5 | 8000 |

Working Principle of Vacuum Belt Filter

The vacuum belt filter uses filter cloth as the filter medium. The filter cloth is laid on a rubber belt with air holes, and the rubber belt runs continuously under the drive wheel.

Feeding stage: the slurry is evenly spread on the filter cloth.

Filtration stage: under the action of the vacuum system, the liquid is sucked away, and the solid is retained on the filter cloth to form a filter cake.

Washing stage: the filter cake is washed in multiple stages through the spray system to improve the recovery rate.

Unloading stage: the filter cloth bypasses the steering roller, and the filter cake is automatically unloaded under its own gravity or the action of the scraper.

Filter cloth cleaning: set a special nozzle to high-pressure wash the filter cloth to maintain the filtering performance.

Filter cloth cleaning: set a special nozzle to wash the filter cloth with high pressure to maintain the filtering performance.

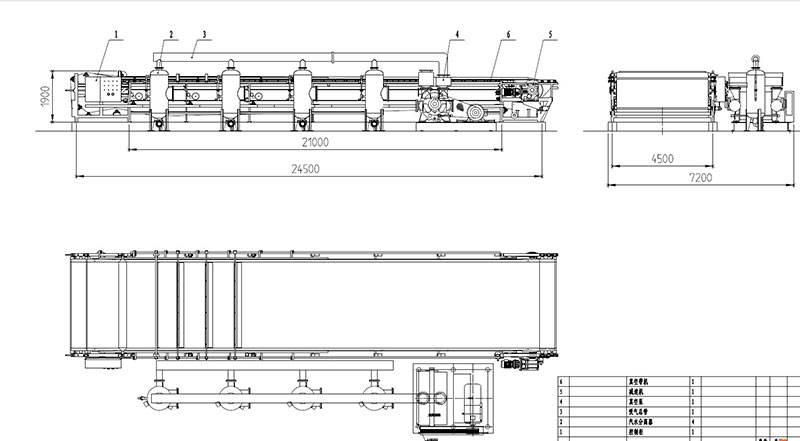

Vacuum Belt Filter Drawing

Core Advantages of Vacuum Belt Filter

Strong continuous processing capacity

The vacuum belt filter can realize uninterrupted feeding, filtering, washing, dehydration and unloading, which is especially suitable for factory production lines with large daily processing volume and long working hours. For example, it is particularly effective in lithium mining, phosphorus chemical industry, ammonium sulfate, sludge treatment and other occasions.

High washing efficiency

The vacuum belt filter supports multi-stage countercurrent washing design, which can greatly improve the recovery rate of the target product and reduce the residual mother liquor in the filter cake. It is very suitable for processes with high requirements for product purity (such as lithium iron phosphate, battery materials, and fertilizer production).

Automation and intelligence

Modern vacuum belt machines support PLC control systems, automatic filter belt deviation correction devices, automatic fault alarms and online filter cloth cleaning systems, reducing manual intervention and improving operational stability.

Long service life of filter cloth

Due to the absence of high-pressure extrusion process, the filter cloth is not easily damaged, which saves maintenance costs compared to the frequent cloth replacement problem of filter presses.