What is a Flocculant?

A flocculant is a chemical agent commonly used in solid-liquid separation processes, playing a crucial role, especially in filter press systems. It works by altering the surface charge of suspended particles, causing tiny particles to aggregate into larger flocs, thereby improving filtration efficiency, shortening the filtration cycle, and reducing the moisture content of the filter cake.

Definition of Flocculants

Flocculants are a class of polymeric compounds commonly used to treat liquids containing suspended solids. They promote the aggregation of fine particles into flocs, facilitating subsequent sedimentation or filtration.

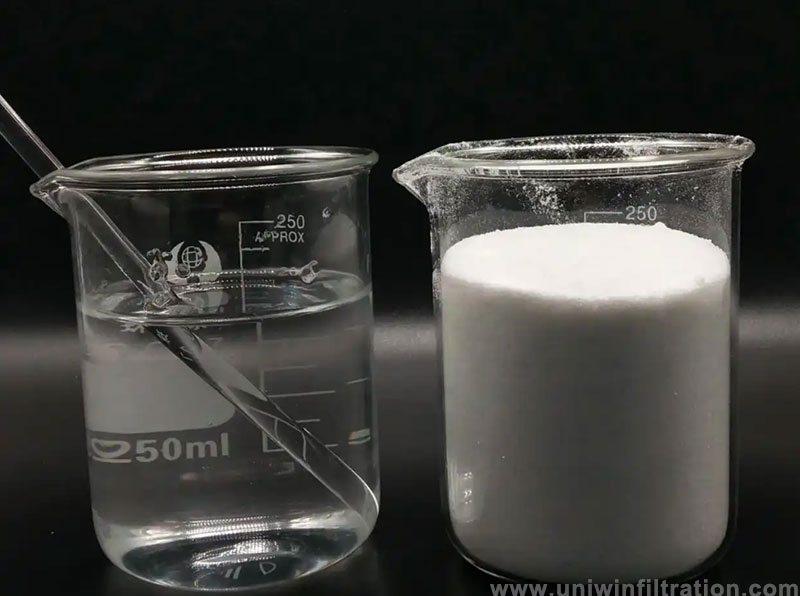

In filter presses and their associated solid-liquid separation systems, PAM (polyacrylamide) and PAC (polyaluminum chloride) are two common flocculants and coagulants frequently used in combination. They exhibit excellent synergistic effects when treating high-turbidity wastewater, sludge, and slurries, significantly improving filtration efficiency and filter cake quality.

Main Function of PAC

Charge neutralization

PAC contains high-valence aluminum ions, which can neutralize the negative charge on the surface of suspended particles, break the colloidal stability, and promote the initial aggregation between particles.

Generation of microflocs

The hydroxyl complexes generated after PAC hydrolysis have adsorption bridging effects, enabling the rapid formation of microflocs, suitable as the “basic framework” for subsequent PAM action.

Improved initial flocculation rate

When the feed rate is large or the suspended solids concentration is high, the rapid reaction performance of PAC significantly improves the initial flocculation efficiency, creating conditions for the action of PAM.

Main Functions of PAM

PAM is a high-molecular-weight chain structure with strong adsorption and bridging capabilities.

Bridging and flocculation

PAM molecular chains can simultaneously adsorb multiple micro-flocs, achieving a “bridging” effect, causing the micro-flocs to form large, stable flocs.

Accelerates settling speed and improves filtration efficiency

Large, well-structured flocs facilitate rapid settling or dewatering during filter press operation, shortening the filter press cycle.

Increases filter cake thickness and reduces moisture content

The strong floc structure provides excellent drainage, promoting the formation of a drier filter cake in the filter press.

Improves filtrate clarity

Significantly reduces suspended solids content in the filtrate, improving the cleanliness of the treated water.

Advantages of Using PAC + PAM Together

In filter press feeding systems, PAC and PAM are often used in combination according to the following steps:

First, add PAC (pretreatment stage)

Neutralizes the charge and initiates initial flocculation to form stable micro-flocculations.

Then, add PAM (enhanced flocculation stage)

Builds large flocs, improving dewatering and sedimentation efficiency.

- Highly adaptable, capable of handling various complex systems such as industrial sludge, wastewater, and mineral slurries.

- Fast flocculation speed, shortening floc formation time and ensuring more stable feed for filter press.

- Good filter cake formation, with a complete filter cake structure and thorough dewatering, facilitating subsequent treatment.

- More cost-effective; compared to using PAM or high-dose PAC alone, combined use yields better results and requires lower reagent dosage.

- Clearer filtrate, improving effluent quality and reducing the burden on subsequent treatment processes.

Conclusion

PAC provides initial coagulant aid, while PAM plays a crucial role in floc structure stabilization and subsequent filtration. The combination of the two not only significantly improves filtration efficiency but also reduces reagent costs and operating energy consumption, making it one of the most common and effective chemical treatment combinations in modern filtration systems.