What Materials are Used to Make Filter Presses?

The choice of material for filter press plates directly affects the equipment’s performance, lifespan, and suitability for different operating conditions. Different filter plate materials have their own characteristics and are suitable for different types of solid-liquid separation processes. The following is an introduction to common filter plate materials to help you choose the most suitable filter plates.

Standard PP Filter Plate (Non-Pure Polypropylene Filter Plate)

Raw material composition: Made from a mixture of recycled polypropylene and fillers (such as talc powder and calcium carbonate) through injection molding.

Appearance features: The plate surface is grayish or yellowish in color, lighter in weight, and has a slightly lower surface finish than pure polypropylene filter plates.

Performance characteristics

- Compressive strength, corrosion resistance, and aging resistance are inferior to pure PP filter plates.

- Due to the inclusion of fillers, the structural density and toughness are slightly lower.

- The cost is significantly reduced, making it suitable for projects with limited budgets or short durations.

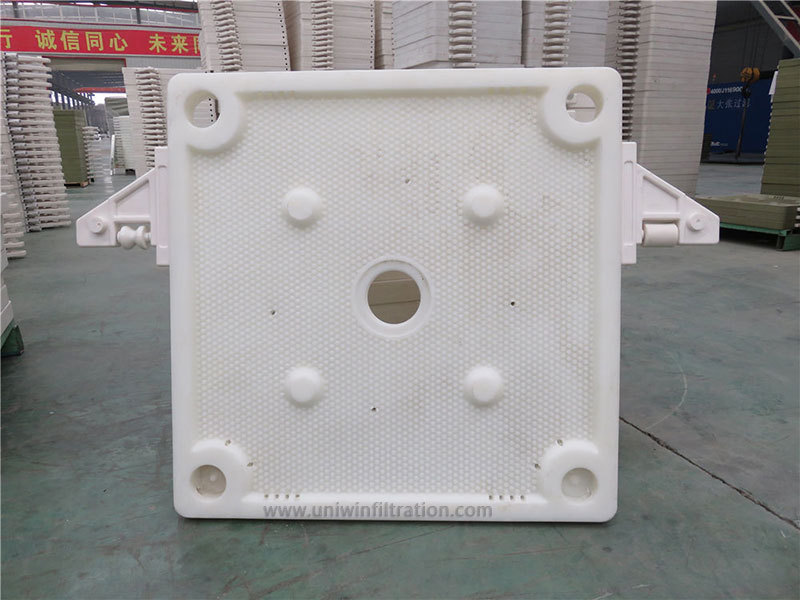

Pure Material Filter Plates (100% Pure Polypropylene Filter Plates)

Raw material: Made from high-purity polypropylene (PP) granules, without the addition of recycled materials, talc, or other fillers.

Process: One-time injection molding, free of impurities and interlayer defects, resulting in a dense structure.

Color: Typically milky white or light yellow, with a glossy finish and uniform texture.

Performance advantages

- Excellent acid and alkali resistance and corrosion resistance.

- Strong pressure resistance; not prone to deformation or cracking.

- Suitable for industries such as food and pharmaceuticals, where high material purity is required.

- Service life is 30-50% longer than filter plates made with fillers.

High-Temperature Filter Plates (with Special Formulation)

Material: Made from conventional filter plate materials with the addition of a special formula.

Temperature resistance range: Up to 110℃ ~ 130℃, superior to ordinary PP.

Color: Generally dark yellow, with a noticeable color difference compared to ordinary filter plates.

Performance advantages

- Combines the dual characteristics of lightweight design and high temperature resistance.

- Suitable for processes involving high temperatures or requiring heating and insulation.

Stainless Steel Filter Plate

Commonly used steel grades: 304, 316

Manufacturing method: Laser cutting or welding + high-precision machining

Performance advantages

- High strength, high temperature resistance, and corrosion resistance.

- Does not easily contaminate materials, meeting GMP requirements.

- Can be repeatedly cleaned and steam sterilized.

- Long service life and overall lower operating costs.

Cast Iron Filter Plates

Material: Cast Iron

Features: Heavy-duty structure, wear-resistant, impact-resistant, and high-temperature resistant.

Performance advantages

- Excellent performance in high-pressure filtration applications.

- Suitable for materials with high solid content, large particles, and strong abrasiveness.

- Long service life, but maintenance is slightly more complex.

How to Choose the Appropriate Filter Plate Material?

Clarify process parameters

- Liquid temperature range.

- Solution pH range.

- Whether the filtrate involves food, pharmaceuticals, or high-purity materials.

- Particle size and hardness of the filter cake.

- Filtration pressure and frequency of use.

Prioritize eliminating unsuitable materials

- If the temperature exceeds 90℃, exclude ordinary PP.

- If strong corrosive or high-temperature solvents are present, exclude ordinary filter plates.

- If GMP or food-grade requirements are involved, exclude filter plates that do not meet food standards.

Select according to requirements

- For high demands on lifespan and reliability: Prioritize pure PP, high-temperature PP, or stainless steel.

- For limited budget and mild operating conditions: Ordinary PP can be used.

- For scenarios where strength is a priority: Choose stainless steel or cast iron.

- For high temperature and corrosion resistance: Modified reinforced PP or 316L stainless steel is preferred.

Consult the manufacturer or request sample testing

For special filtration materials or complex liquids (such as those containing oil, salt, or particles), it is recommended to communicate with the manufacturer for sample testing.

Testing includes pressure resistance testing, corrosion resistance testing, and filtration efficiency comparison.

Conclusion

Choosing the appropriate filter plates is one of the key factors in ensuring stable, efficient, and durable operation of the filter press. Different filter plate materials have varying suitability in terms of corrosion resistance, temperature resistance, mechanical strength, and cleanliness. Therefore, the selection should be made rationally based on actual conditions.